How To Correctly Use A 3 Way Valve In Different Applications

Posted by Jason Welsford on May 17th 2022

To understand the "T"-port and an "L"-port 3-way valves and what makes them different, it's important first to establish what each of these terms mean. By clearly defining each term, the difference in directional flow purpose will be easier to understand. First, let's define exactly what a diverter valve does.

In simple comparison, a 3-way valve has one more port than a 2-way valve. But why? A two-way valve allows fluid to enter the valve from one port, and exit through the other. Having a third port, allows fluid an alternate path of travel, either when exiting or entering the valve. This permits fluid to either exit the valve from more than one point, or enter the valve from more than one point.

Several industrial applications use 2-way valves that provide on/off fluid service. Applications that require constant flow utilize 3-way valves, which contain three connection ports, having A, B and AB labels. 3-way valves can divert fluid flow to two directions or mix fluids from two different sources.

When using 3-way valves for mixing, fluids enter the valve body through ports A and B. The service fluids with different physical or chemical properties mix within the valve body before transmission through the outlet port AB. 3-way mixing valves are vital for combining liquids or gases with different temperatures and pressure, before sending them through the outlet with the desired properties.

For 3-way diverting valves, port AB acts as the inlet, while ports A and B become the outlets. Turning the spindle directs the flow to the left or right, upwards or downwards, depending on the orientation of the piping system. When flow moves from AB to A, the valve blocks fluid flow to port B. Changing the position of the spindle redirects the flow of fluids from AB to B and blocks the flow to port A.

Related products

[[86,603,1338]]

3-way valves are available in two internal structures. They are either L-type (L-port) or T-type (T-port) valves. The internal structures of the valve determine the flow patterns past the valve body. The T-port design is suitable for distributing common inlets to different destinations and the L-port design facilitates mixing from multiple sources to common outlets. 3-way valves, like the 2-way counterparts, can use actuators that improve their responsiveness and enhance precision in different industrial applications.

The multiport configurations of 3-way valves make them cost-effective alternatives to using multiple 2-way valves with complex automation. A single 3-way valve can provide directional fluid control and shut off. These valves offer reliable fluid service in heating and cooling applications, steam and boiler applications, chemical mixing processes, hydraulic and pneumatic applications. 3-way valves are also suitable for use as by-pass valves in pipe systems having primary and secondary loops.

L-Port Versus T-Port 3 Way Valves

There are different multi-port valves available in the market, ranging from 3-way ball valves, 3-way globe valves, 3-way butterfly valves and 3-way gate valves. 3-way ball valves are the most popular due to their simple design, ease of actuation and durability. The control of fluids past these valves depends on:

- The pipe set up: is the pipe system horizontal or vertical?

- The direction of handle rotation

- Design of the port: L-port or T-port?

The subsequent discussions regarding L-port and T-port designs refer to 3-way ball valves. Valve manufacturers provide arrows on the valve handles that mimic the fluid flow paths through the control mechanism. These marks indicate flow directions.

L-Port Valves

The L-port, L-pattern valve allows the convergence of fluid from two different inlet ports without ever using the same inlet port and directs it to a common outlet. They have two inlets and one outlet port. L-port valves can provide fluid diversion service in some applications. Assume inlet ports (A and B) are horizontal, and the lower port (AB) is the outlet. The initial flow is from the inlet port (B) to the outlet (port AB).

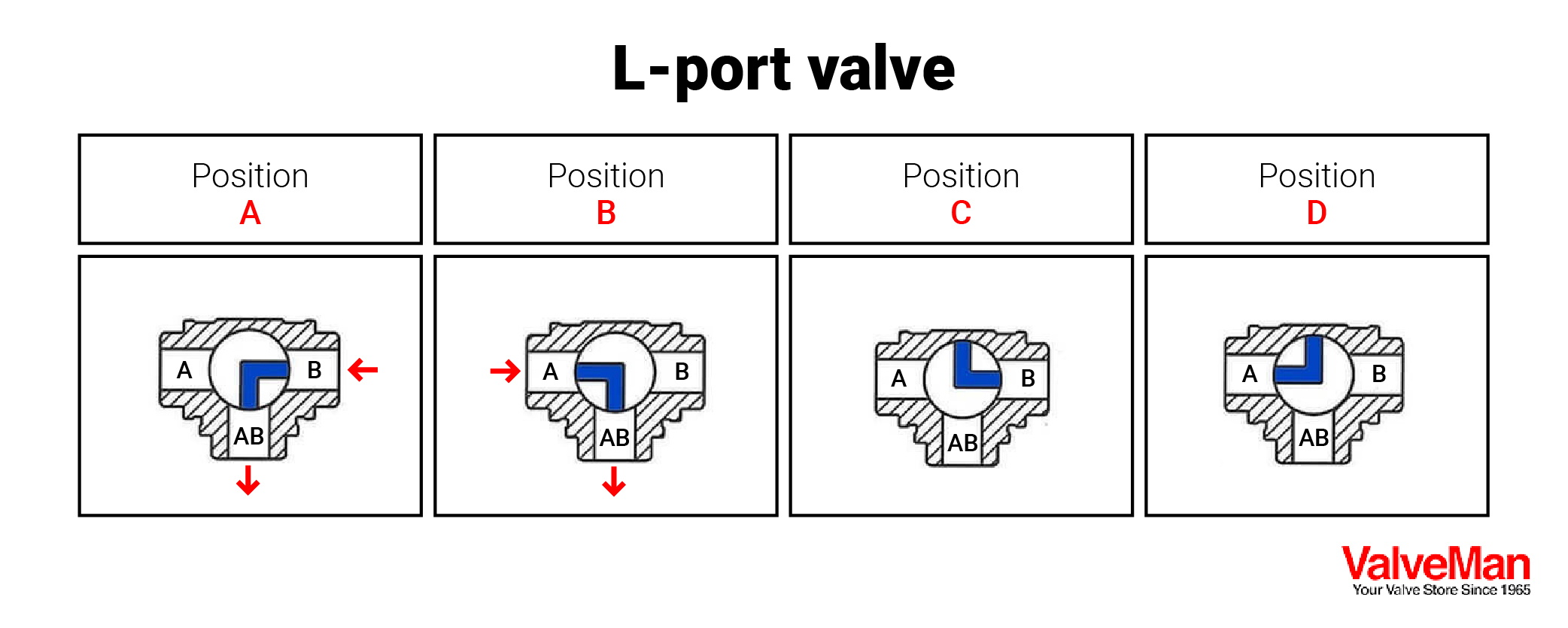

Possible Flow Positions (A, B, C and D) In The L-Port Valve

Shifting the valve lever or the actuator through 90° clockwise changes flow direction from port A to common outlet AB.

Turning the lever through another quarter-turn moves the valve through 180°. At this point, the 3-way valve shuts off the flow of fluid past the valve. Some L-port valves can move through 360°, providing two shut-off positions. In a vertical L-port orientation, the outlet port (AB) is always in an open position.

Applications of L-port Valves

The versatility of L-port valves implies that they can provide shut-off, directional control, fluid diversion or bypass where necessary. A typical application of L-port valves (vertical or horizontal) is alternating sources of fluids in a process.

T-Port Valves

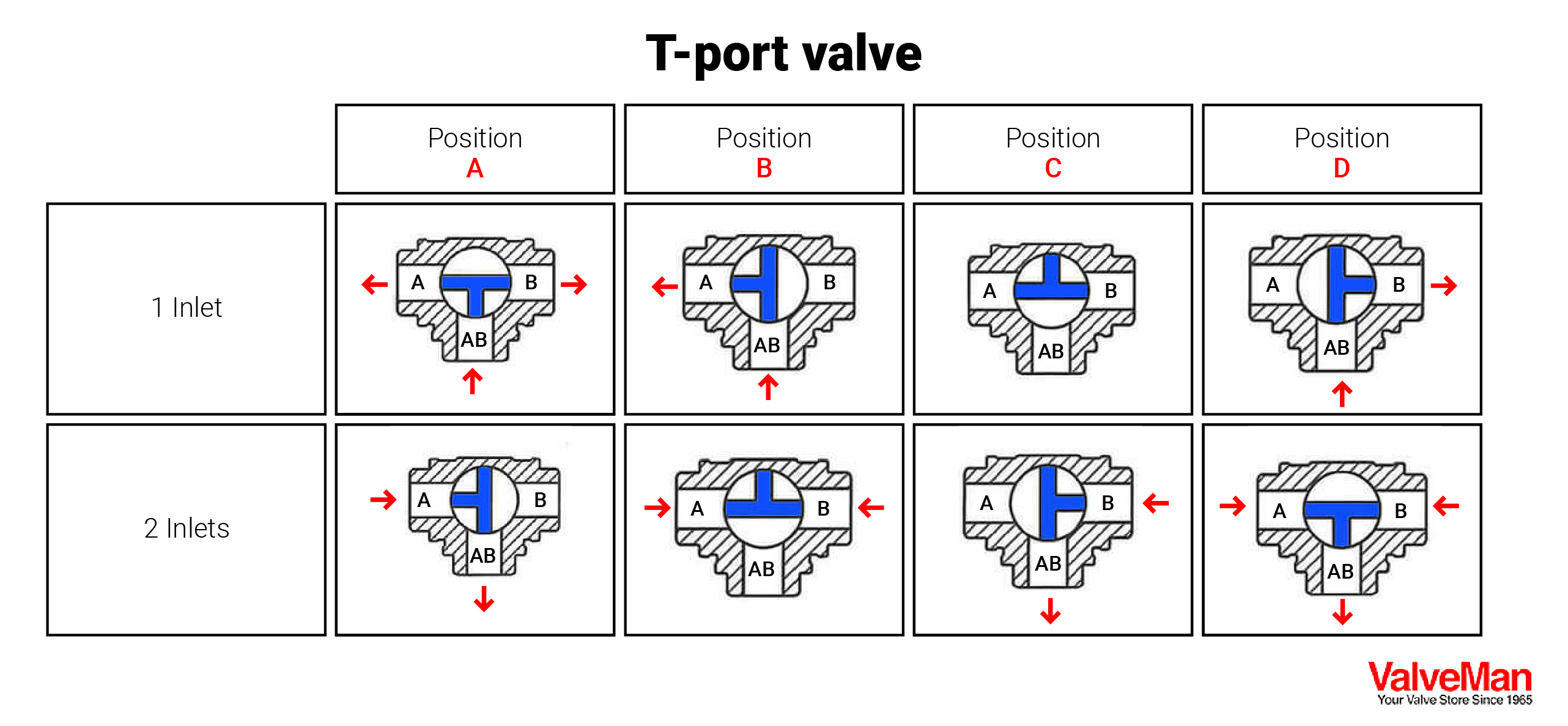

T-port valves primarily divert fluids from one source to different outlets or mix two sources to a single outline. The valves split or divide the flow of fluids into two directions. Flow enters the valves through one inlet and flows to two destinations.

T-port or mixer valves can have all three ports open at once. The T-pattern allows the service media to flow in two opposite directions or a straight-through flow. The common port is always open if the T-port valve is vertically-configured.

Possible Flow Positions (A, B, C and D) In The T-Port Valve

Turning the valve lever or actuator through a quarter-turn diverts the flow of fluids to either direction - like an L-port valve. T-port valves cannot provide an "all ports closed" configuration. Three-way valves can have lock handles that prevent the flow control mechanisms from exceeding the 90° turns, however, they can also have 180° or 360° rotation. Limiting the motion of the ball or flapper offers better control over the volumes of fluid to divert or mix within the valve body.

Applications of T-port Valves

T-port valves can provide constant fluid flow service, media mixing and sampling. They are also suitable for use as bypass valves. Some general industrial applications of T-ported valves include:

- Merging fluid flow from two different sources. For instance, in a piping system in a beverage production line, the valve may serve as a primary combination point for fluids coming from a pure water line and a juice concentrate storage tank.

- Diverting flow from a single source to two different destinations at once. It’s important to keep the pressures of the inlets balanced and higher than the outlet port in order to allow for a smooth mixing process

- Changing flow between two storage tanks or destinations (when used like an L-port valve)

Tips For Selecting and Maintaining 3 Way Valves

There are a few guidelines that pipeline engineers and designers should consider when selecting 3-way valves for different industrial applications. Some critical tips include:

- Choose the appropriate valve sizes. Undersizing the 3-way valve will increase the pumping costs of the system. Oversizing the valve reduces pumping costs but will cause control inaccuracies. Valve movements at the beginning and the end of travel will have minimal effects on the distribution of fluids past the ports.

- Evaluate the physical and chemical qualities of the service fluids. If using the valve for mixing, the valve material and sealing components must be compatible with the service media. Valve materials must adhere to statutory regulations and certification standards.

- The pressure and temperature ratings of the 3-way valves should accommodate the flow conditions and variations of the service fluid.

- Confirm the connection types of the 3-way valves to ensure they are compatible with the existing pipelines. When choosing the valves, select a connection method that will simplify the maintenance of the piping system, valves and actuators. 3-way valves having flanged connections are easier to maintain and replace than their welded counterparts.

- Also, consider the actuation mechanisms. What type of actuators will meet the requirements of the piping system?

Conclusion

The multiport configurations of 3-way valves allow better flexibility and control in different industrial applications. The valves have different internal designs that give them unique performance characteristics. The capability of a single 3-way valve to handle the diverse flow applications implies that fewer valves are required. It reduces the cost of installation, operations and maintenance. If you’re unsure in your selection, make sure to consult a valve engineer at ValveMan.com to help you make the right decision.

888-825-8800

888-825-8800