Understanding Valve Sizes and Measurement

Posted by Jason Welsford on Sep 3rd 2024

Sizing the appropriate valve is critical to ensuring the performance of your system. Whether you're into industrial process piping, utilities, HVAC, or plumbing, it is important that you understand how valves are sized and through what methods of measurement. Don't be intimidated if unsure about anything: ValveMan is here to help. We'll be covering the very basics of valve sizing here and walking you through specifying and selecting the proper valve size. We shall also examine valve measurement and emphasize several significant measurements that warrant consideration.

Armed with the proper knowledge, selecting the right size of valve for your project would be as easy as ABC. Let's get down to business.

Importance of Valve Sizes

The valve size is an integral part of valve selection and application. Basically, the size of the valve determines the flow rate and pressure of a fluid that goes through it within a pipeline. Valve sizes also have an effect on the cost, operating, and maintenance requirements of a pipe system. A properly sized valve is quite important for one to achieve maximum performance and reliability in a pipe system.

Why Correct Valve Sizing is Important

Correct valve sizing is crucial for several reasons. We cover some of them below.

- Limiting pressure drop is an essential consideration; therefore, the valve must be appropriately sized to accommodate the required flow rate while preventing excessive pressure drop or loss within the system. For instance, a butterfly valve may possess a maximum velocity limit to avert potential damage to the valve disc or seal.

- Flow control effectively: valves of the proper size enable appropriate flow control, in addition to enabling the system to function within a wide range of flow. A number of valves such as check valves and control valves should be selected with proper correspondence to system requirements regarding flow and pressure. Such valve selection based on pipe size may result in incorrect valve selection.

- Smooth operation and stability: Correct valve sizing maintains stability and smothers operations. This is because large or small-sized valves for the application often relate to noise and vibration.

Improper Valve Sizing and Its Consequences

Unduly sized valves can present a number of problems. Each will be covered below.

Excessive energy use: The wrongly sized valve will restrict the flow passing through it, leading to a major pressure drop or head loss across the valve. This subsequently results in higher energy usage by process machinery such as pumps, fans, and compressors. Increased cost: A larger valve costs more, and if the valve size is not correct for the application, this is a wasted expenditure. Incorrectly sized valves also suffer from increased wear and tear and potential failure, resulting in greater maintenance and replacement costs. The greater of the dangers arising from inadequately sized valves is water hammer and cavitation. The resultant noise and vibration, together with the stresses induced in the nearby pipework and equipment, will serve to reduce system performance and create conditions dangerous to personnel.

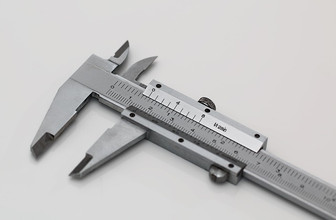

Understanding Valve Measurements

Understanding the measurement of valves is essential for selecting the appropriate valve for a given application. Valves are generally measured according to their connection size and type. Moreover, dimensions that are crucial to the operation and compatibility of valves within a piping system are of significant importance.

Image from Wikimedia Commons

What are Common Units of Measurement for Valves?

Valves can be quantified using various units depending on the measurement of interest. The most common units of measurement include the following:

- Inches (in) or millimeters (mm) for dimensions such as diameter, length, and height.

- in² or mm² for the flow area or orifice area of the valve.

- Pressure ratings are in pounds per square inch (psi) or bars (bar).

The units serve to present physical sizes, flow rates, and pressure ratings of the valves, assisting in the selection of a valve that would meet the needs of any system.

Key Valve Measurements

Accurate valve measurement is essential when replacing valves. Here are some important points to consider:

- Since the measurements differ by type of valve, one must identify the type of valve in question: is it a ball valve, a gate valve, a butterfly valve, a globe valve, or a check valve?

- The type of connection shall be determined: the valve is flanged, threaded, or welded. The connections are according to international standards like ANSI, ISO, or DIN. Therefore, the size measurement of a valve needs to determine the type and standard of connection used.

- Measure the connection size: This is generally defined as the diameter of the pipe to which the valve will be connected, and it is frequently measured in either inches or millimeters. Pipe sizes are standardized and are often expressed in nominal sizes or pipe bores.

- Calculate flow area: Either the measurement of valve flow area or orifice size refers to the opening inside a valve through which the fluid passes. This is crucial as it depicts the flow rate and the fluid velocity through the valve.

- Check for the pressure rating: You must know the pressure rating of the valve, which must be able to withstand the maximum operating pressure of the system. Pressure ratings may either be in psi or bar.

- Check the specifications: The measurements should be checked against the manufacturer's specifications, as well as compatibility with your system.

For intricate systems or particular applications, it is advisable to consult with a valve specialist or engineer in order to guarantee precise valve sizing and selection.

Guidelines for Selecting the Appropriate Valve Size

Sizing the proper valve can ensure that liquids and gases flow smoothly, efficiently, and safely through piping systems. This involves more than just matching pipe diameter; several other critical variables are leveraged in making an informed decision.

Factors to Consider in Valve Size Selection

The size of the valve will depend on a number of factors. Some of these include:

- Flow rate: The amount of liquid that needs to travel through the valve has a direct impact on the size needed. A valve not sized correctly will restrict flow, which could cause pressure drops, reducing system effectiveness.

- Application: The nature of the fluid, temperature, pressure, and if there is any particulate matter determines the material and design of the valve, which in turn determines size options.

- Connectivity: Valve sizes must match the connecting pipe sizes to prevent leaks and ensure seamless integration into the piping system.

- Pressure drop: The allowed pressure drop through the valve should be understood. Too much loss in pressure can result in a reduction in performance of the downstream equipment.

- The actuation method may be manual, electric, pneumatic or hydraulic. The method employed to open and close the valve influences the necessary size and configuration of the valve.

Recommendations for Sizing Valves

Following are some recommendations concerning valve sizing:

- Refer to the sizing charts provided by the manufacturers: Valve manufacturers provide sizing charts based on flow rate, application, and material that make selecting a valve easier.

- Use advanced valve sizing software: Software packages can be used that calculate system requirements and suggest the best sizes. These are especially useful for control valves.

- Seek advice: In doubt over any matter, an engineer or any other valve system professional could be consulted. Advice would be given on certain needs and application of the system.

Valve Sizes & Measurement - Final Thoughts

Proper valve selection requires a deep consideration of valve sizing. Once the principle of valve sizing and how sizes are measured is understood, your selection will perfectly match your system's needs. Remember, it is not about finding a valve that fits but finding one that will work properly in your environment. This way, you will achieve optimal performance and duration for your system.

If you're interested in learning more about all things valves, take a look at some of the following articles:

Understanding valve standards and specifications

Understanding different types of valve connections and fittings

888-825-8800

888-825-8800