Valve Inspection - Main Points of Valve Inspection and Testing in Manufacturing Settings

Posted by Mark Trainer on May 16th 2025

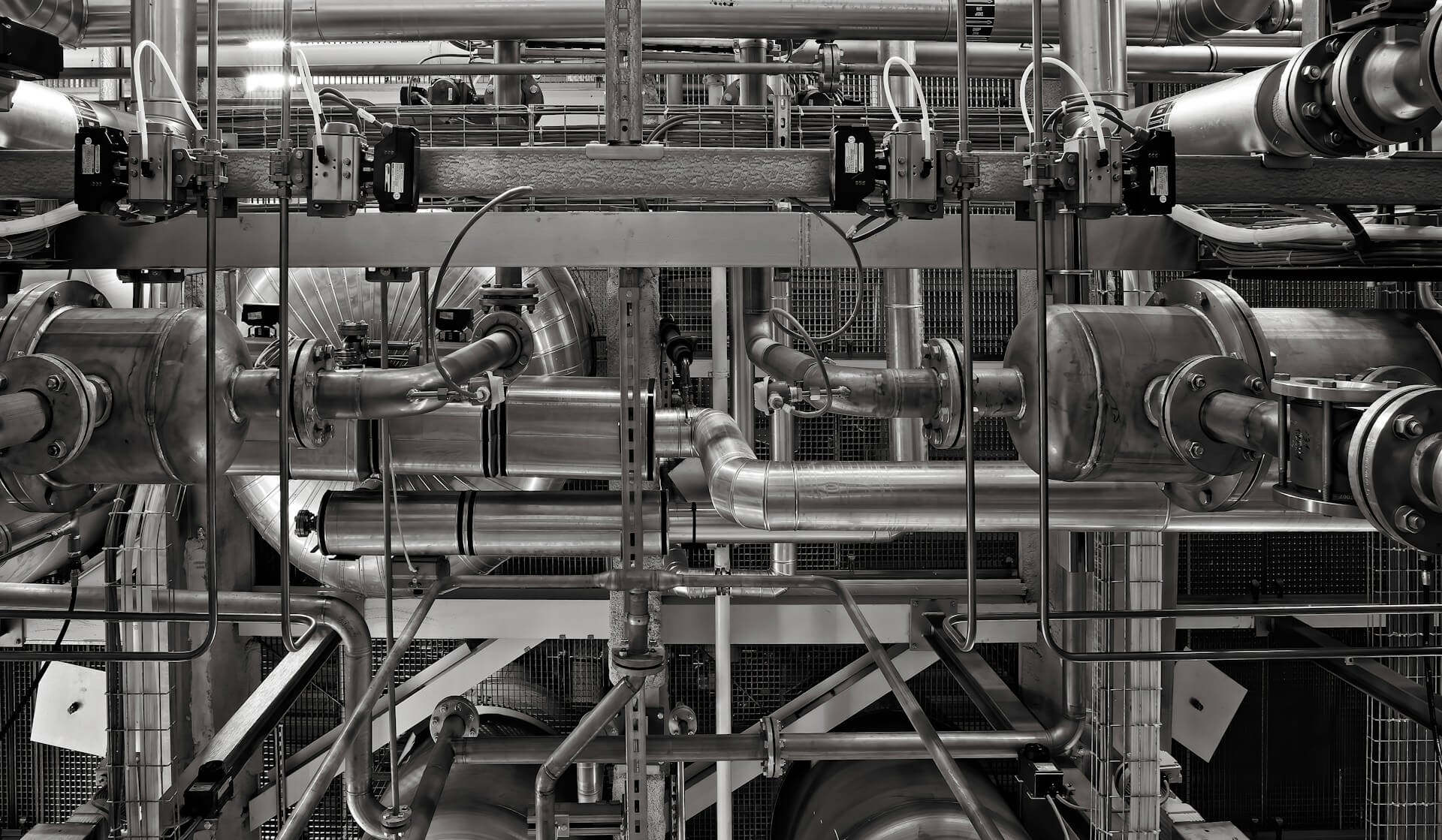

Industrial facilities rely on different types of valves (such as gate valves, check valves and ball valves) to control fluid flow, which is critical for the successful operation of many manufacturing processes. The design and manufacture of industrial valves follow stringent codes and standards to ensure valve performance, prevent valve failure and guarantee that valves are safe, durable, simple to operate and maintain.

Key Points

- Standards for Valve Production: Industrial valves are designed and manufactured to meet codes and standards which ensure durability and performance.

- Stress and Strain on Valves: Valves are exposed to many stresses, including pressure and temperature variations in processes.

- Valve Inspection and Maintenance: Regular inspections are crucial to detect signs of fatigue and prevent valve failures.

- Non-Destructive Testing for Valves: Techniques like ultrasonic testing and liquid penetrant testing may be used to detect material defects.

- Comprehensive Valve Testing: Essential for ensuring valve integrity under operating conditions.

Valves in service may undergo cyclic loading due to pressure and temperature fluctuations. Valve components may also corrode due to physical and chemical properties of the process fluid, or exposure to environmental conditions. Aside from wear and tear, exposure to vibration, cavitation and pressure surges can impact valve performance, and also increases valve susceptibility to failure. Valve failures can have serious consequences for industrial and manufacturing operations, ranging from costly downtime to product wastage, process inefficiencies and safety risks.

Manufacturing facilities use various valve inspection techniques to identify early warning signs of valve fatigue and failure – which may result in reduced valve performance, lower process efficiency, leakages, and loss of product containment. Valve inspections are critical not only during initial installations, but throughout the lifetime of industrial valves. In many facilities, valve inspection forms part of routine maintenance activities and happens at predetermined intervals.

Regular valve inspections following industry-approved standards – such as API 598, API 6D and ISO 5208 – enable maintenance supervisors to pro-actively identify and replace valves, before valve or process failures occur. For example, non-compliant valves with high leakage rates may be replaced during a planned shut-down, in order to enhance valve efficiency and improve the overall effectiveness of the production process. What are the most critical valve inspection points in a manufacturing facility?

1) Valve body

The valve body houses internal valve components and is the primary pressure boundary with maximum exposure to fluid pressure. As fluids undergo momentum change at the valve, the resultant pressure acts against the valve body.

Valve bodies are made from materials possessing unique physical properties to protect them from premature damage or rupture, due to fluid pressure or other forces. However, over time, valve bodies are liable to failure. Valve bodies also resist corrosion from the chemical composition and viscosity of the service fluid, as well as the installation environment. The shell, often subjected to a pressure test, undergoes repetitive expansion and contraction in service, due to the variation of process pressures and temperatures. Even if the contraction and expansion is minute, their long-term impacts are noticeable on a valve life expectancy.

Inspecting valve bodies provides valuable insight into the resilience and potential durability of the valve. Fatigue due to fluid temperature and pressure cycling may cause cracks and crevices on the valve surface; these cracks are sometimes visible to the naked eye, even without visible signs of leakage. There could be noticeable signs of corrosion on the surface of a valve due to chemical attack from the service fluid, due to environmental exposure conditions, or due to a gradual loss of protective coating.

Technicians and maintenance personnel can leverage non-destructive testing (NDT) techniques to inspect valves for surface irregularities and cracks. Valve wall thickness may also be established through NDT techniques. The most popular defect detection methods include ultrasonic testing, radiographic testing, eddy current testing and penetrant testing.

2) Flanges, Gaskets and Fasteners

Flanges are one of the primary methods used to connect valves to adjacent pipework, fittings and equipment. Valve flanges are often cast integrally as part of the valve body, and comply with flange standards such as ANSI/ASME B16.5, SAE, EN 1092 or ISO 7005. Valve flanges are connected to pipes by bolting the valve and pipe flanges, with a gasket placed between the flanges to provide a leak-tight seal. Fasteners used for connecting pipes and valves are adjusted to a specific torque, which also depends on the line's pressure and temperature rating. Correct valve installation, including fit and bolt-up, ensures that valves and pipework are secure and prevents valve misalignment. Incorrect valve installation may impede flow or cause vibrations, affecting operations of related pipe sections.

It is vital to inspect flanges, gaskets, and fasteners during valve inspection and maintenance in industrial and manufacturing facilities. Loose connections, worn-out gaskets, or defective flanges can lead to process inefficiencies, leakages and fugitive emissions. Some inspection methods for these components include:

- Visual inspection of flange ends, gaskets, and fasteners. Technicians can identify flange defects such as cracks, as well as rusty, broken, or missing fasteners.

- Ultrasonic or surface testing of welded flanges to evaluate thickness and identify surface defects such as tiny cracks.

- Using torque wrenches to check the torque applied to flange connections.

- Bolting-up valve flanges in the correct sequence, typically a criss-cross or star pattern.

It is vital to replace worn-out or damaged gaskets immediately. Damaged gaskets are unsuitable for high-pressure or high temperature applications as they increase the risk of joint failure, and also present a safety risk. When replacing damaged valves, one should note the required flange surface finish, end-to-end or face-to-face flange dimensions, fastener hole diameters and pitch circle diameter (PCD), and flange thickness.

3) Valve Discs, Seats and Seals

Internal valve components like disks, shafts and seats come into direct contact with fast-moving, abrasive or corrosive service fluids. Internal valve components must be selected and optimized for media compatibility and durability. However, despite adhering to stringent manufacturing and quality standards, internal components such as seats, seals and discs may undergo wear, erosion and corrosion, which causes valve performance to decline and often results in reduced sealing efficiency.

Internal valve damage may be difficult to notice - inspecting discs, seals, and seats is often only possible during a scheduled process unit or plant-wide shutdown. Automated condition monitoring processes utilize sensing devices to monitor valve performance over time. Changes in valve performance may indicate underlying defects, production teams can plan a temporary shutdown for maintenance technicians to conduct further investigations, including inspections and rectifying the problem.

Depending on the application, we recommend that internal valve components are inspected annually. Severe service valves and gas ball valves should be inspected in shorter intervals to ensure that components such as seats and seals are in perfect working condition. The valve trim is often designed to be replaceable. Any trim components that exhibit signs of excessive wear or fatigue should be replaced. A good approach is to inspect and assess the status of disc connection points, shafts, return springs, and evaluate the thickness of the flow control element (ball, disc, or gate).

When non-metallic seals age, they become brittle, while some might even begin rotting. The ease of replacing these seals depends on the design of the valves. It takes less time and effort to replace seals in 3-piece ball valves than in 2-piece configurations. 3-piece ball valves have two detachable end caps and a central section; removing the end caps provides easy access to seals. Access to seals for inspection and replacement should be considered when specifying a valve, many valves require removal from the line before seals can be replaced.

4) Valve Stem and Actuation Mechanisms

The stem, which connects internal valve components to the actuator, lever or handwheel, undergoes corrosion due to the chemical action of fluids. It also experiences surface wear and tear (due to friction between the stem and the packing as it moves to open or close the valve). The valve stem, also referred to as valve shaft, experiences torsional and compressive stresses applied by the actuator. As such, valve stems may fail if not inspected regularly.

Actuators provide the force to open and close valves, typically in the form of electric, pneumatic or hydraulic actuation. It is important to note that an actuator that is not properly mounted to a valve will wear out the valve stem exponentially faster than a properly mounted actuated. An oversized or undersized actuator may damage the valve or actuator itself. Ensure your products are specified, assembled and tested by a reputable source prior to installation.

Inspection points for valve stems include:

- A build-up of ground metal, rust or plastic

- Loose connection points (including bolts and nuts)

- Level of play or tightness of the stem

Inspections of actuation mechanisms depend on the type of actuator used. When inspecting electric actuators, check if electrical terminals, connectors, cables, and casings are well insulated. Check the power ratings of the external power supply, cleanliness of motors and lubrication on moveable parts like bearings. When handling hydraulic and pneumatic actuators, inspect cylinders, fluid supply systems, and filters.

Comprehensive Valve Testing - Ensuring System Integrity

Regular valve inspection and testing is an important factor in industrial and manufacturing settings, and focuses on different valve types such as check valves, control valves, safety valves and isolation valves. This essential maintenance activity involves a number of tests, each one tailored to assess specific valve conditions and performance parameters.

Key Testing Procedures

Valve pressure testing determines whether valves are able to withstand their operational and rated pressures. Valve seat tests ensure the interface between the valve disc and seat is tight enough to prevent valve leakages, or allow an acceptable leakage rate through the valve. The valve shell test - also called the valve body test - assesses the general strength and integrity of the valve under pressure.

Specialized Valve Type Testing

Distinct valve types, such as globe valves, check valves and air valves, require specific tailored testing protocols. Globe valves are tested for their ability to control fluid flow over a range of flows and opening percentages. Tests on check valves will ensure the complete prevention of backflow, and may investigate the cracking pressure required to open the valve. Depending on their type, air valves may be tested with regards to intake and exhaust air capacity, which is a measure of the amount of air they admit or release from a pipe.

Advanced Valve Inspection Techniques and Safety Protocols

Advanced valve inspection techniques are important in maintaining the safety and functionality of industrial fluid systems - these inspections are more than just basic evaluations, and take into account the intricacies of valve construction, operating conditions and installation environment. Specialist personnel are required to perform advanced valve inspections and condition assessments. These include non destructive testing (NDT), acoustic emission monitoring (AE), and phased array sequence scanning (PASS).

Preventing Valve Failures

Rigorous inspection plays a vital part in preventing valve failures. This includes checks of valve seat surfaces and trim, which is usually only possible during scheduled maintenance activities, as well as the condition of the valve shell. Regular valve inspections help identify early signs of wear and damage, such as cracks or corrosion, particularly in critical components like valve discs and seats.

Conclusion

Valve inspection is an important part of routine maintenance activities in a manufacturing facility. Comprehensive asset management plans, including installation, operations and maintenance checklists, must be used to ensure adequate and timely maintenance of process valves.

In closing, valve inspection allows companies to identify and rectify underlying defects and also extends valve durability, while facilitating uninterrupted continuity of industrial and manufacturing processes. It also guarantees optimum operational safety. Valve inspections may combine manual and automated inspection techniques, and may depend on the number of valves, accessibility of valve chambers, and the intensity of valve inspection tasks.

Need guidance in determining the right valve for your industrial, process or manufacturing application?

888-825-8800

888-825-8800