What is a Spool Valve and How Does It Work?

Posted by Gilbert Welsford, Jr on Jan 27th 2026

Spool valves are incredibly useful. They are a simple directional control valve used in hydraulic and pneumatic systems to block or redirect fluid flow. In these systems, the fluid powers critical components, such as hydraulic motors or pneumatic cylinders.

In this blog post, you’ll learn how they work, what the most common configurations are, and how they are actuated. Let’s dive in!

How Does a Spool Valve Work?

In a nutshell, a spool valve uses a cylindrical plunger contained within a valve housing to manipulate the flow of fluid in and out of ports.

Anatomy of a Spool Valve

The cylindrical spool that gives these valves their name has both lands and grooves. The lands are the thick, solid sections of the spool. Precision-machined to near-zero clearance, they can act as seals to prevent fluid from flowing between valve ports. The spool also has narrow, undercut sections known as grooves. The metal has been machined away to create these grooves, which are essentially empty spaces within the valve body. These empty spaces allow fluid to flow in and around the ports.

How the Valve Works

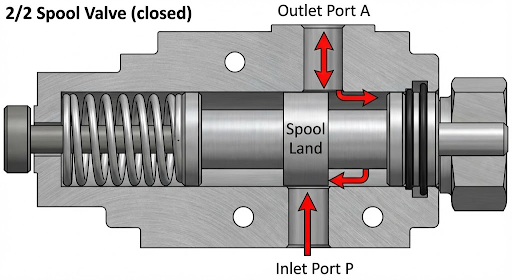

To understand how a spool valve works, let’s consider the simplest version: a 2/2, or two-way spool. It has two ports (an inlet and an outlet) and two positions (on and off). More complex valves (like 4/3 valves) use multiple lands and grooves to direct fluid to different locations, but a 2/2 spool valve uses a single section of the spool to act as a sliding gate.

Most 2/2 spool valves are “normally closed” and have only two positions. Normally closed means that position one is closed because a spring pushes the spool so that a land sits in the middle of the flow path to prevent flow. The fluid will enter the inlet port, but will hit the solid wall of the land. That land creates a seal against the valve housing, preventing any fluid from reaching the outlet port. This is illustrated in the image above, where the land prevents the flow of fluid from the inlet port.

Position two is open (or actuated). When a lever or other actuator is activated, the spool slides, causing the groove to move into the space between the two ports. This allows fluid to enter the valve through the inlet, flow around the narrow neck of the groove, and exit through the outlet.

What are the Common Configurations of a Spool Valve?

Let’s talk about the most common configurations of spool valves.

2/2 Spool Valve

As already discussed, these spool valves have two ports (Input and Output) and two positions (Flow or Shutoff). Theoretically, they work like a water faucet: they either allow flow between the inlet and outlet ports or block the flow. They are best for emergency stops, simple shut-offs, or isolating a circuit branch, and work with both pneumatic and hydraulic valves.

3/2 Spool Valve

These spool valves have three ports (Supply, Work, Exhaust) and two possible positions. In the first position, they allow flow into the machine (from Supply to Work). In the second position, the supply is blocked, and the machine is connected to the exhaust or the tank (flowing from Supply to Tank). These valves are great for single-acting cylinders that extend with pressure but retract with an internal spring or gravity.

4/2 or 5/2 Spool Valve

These spool valves are the standard for moving a cylinder in two directions. In 4/2 (usually used for hydraulics), there are four ports (Pressure, Tank, A, B) and two positions that extend or retract the cylinder. Similarly, 5/2 spool valves, usually used in pneumatic applications, have five ports (Supply, two Work, and three Exhaust). They work much like the 4/2 spool valve, but use the two Exhaust ports for extension and retract strokes. With this configuration, they support better speed control.

Both the 4/2 and 5/2 spool valves work really well for double-acting cylinders that are either extended or retracted without a middle stop point.

Below you’ll see an STC 4A120-420 Series Pilot Operated 4/2 Air Valve with a single air pilot actuator (which we’ll discuss later).

Here is a STC 4V110-410 Series Solenoid 5/2 Air Valve that is also controlled with a solenoid.

4/3 or 5/3 Spool Valve

These spool valves add a third "neutral" position in the middle. They have four ports and three positions. They have two center position options: a closed cylinder that blocks all flow and locks the cylinder in position, and an open center that connects the pump directly to the tank to save energy while the machine is idling. These work great for hydraulic cylinders and log splitters – basically any application where you need to lock a cylinder in mid-stroke.

Here is an example of a pneumatic STC 4A130E-430E Series 4/3 Pilot Operated Air Valve.

How are Spool Valves Actuated?

Now, let’s talk about how these valves are actuated.

2/2 and 3/2 Valves

These values are most often used for basic start/stop functions. The direct-acting solenoid, in which a magnetic coil directly moves the spool, is the most commonly used actuator for 2/3 and 3/2 valves. For 3/2 valves, another standard actuator is a push-button or palm-button control. This type of actuator is typically associated with start or emergency stop buttons.

Below is a STC 2P025-1/8" NPT 2-Way Valve with a direct-acting solenoid.

Another standard actuator used with spool valves is the mechanical roller cam. In this mechanical system, the valve is positioned so that part of the machine (e.g., a sliding table) contacts the roller, which then shifts the spool.

4/2 and 5/2 Valves

This type of valve is most commonly used for moving pneumatic or hydraulic cylinders. One standard actuator is the solenoid pilot, which opens a tiny passage allowing the system's own pressure to push the valve spool. Another type of pilot actuator used in connection with these valves is the air pilot. It is used in explosive environments where an electric spark could be dangerous, so instead it uses a pulse of air coming from a remote location. Finally, you’ll also see simple foot pedals controlling 5/2 valves.

4/3 and 5/3 Valves

These valves have a neutral position, meaning the spool must move to three distinct positions. They may require a manual lever, which can provide precise movement, or a double solenoid with a coil on both ends of the valve. In more massive machines like mining shovels, the main spool may be too heavy for a solenoid to move, in which case hydraulic pilots are used.

Summary of Spool Valve Actuators

|

Valve Type |

Primary Goal |

Common Actuator |

Why? |

|

2/2 or 3/2 |

Sensing / Logic |

Roller Cam or Button |

Simple physical "trigger" for the machine. |

|

3/2 or 5/2 |

Automated Motion |

Solenoid-Pilot |

Allows a computer (PLC) to move heavy rams. |

|

4/3 |

Heavy Lifting |

Manual Lever |

Gives the operator "feel" and a middle stop. |

|

5/3 |

Safe Stops |

Double Solenoid |

Automatically returns to a safe center on power loss. |

Conclusion

Whether you need a valve for a simple pneumatic cylinder or a complex hydraulic system, choosing the right spool valve can be tricky. But a good foundation in how spool valves work, their standard configurations, and how they are actuated goes a long way in helping you with that choice.

Ready to find the perfect fit for your application? At ValveMan, we carry a wide selection of high-performance directional control valves designed for precision and durability. Contact us today!

888-825-8800

888-825-8800