Manual

Manual 3-Way Ball Valves

Shop Manual 3-Way Ball Valves Shop Now

Electric

3 Way Electric Ball Valves

Shop 3 Way Electric Ball Valves Shop Now

Pneumatic

Pneumatic 3-Way Ball Valves

Shop Pneumatic 3-Way Ball Valves Shop Now

L-Ported

L Valves

Shop L Valves Shop Now

T-Ported

T Ported 3-Way Ball Valves

Shop T Ported 3-Way Ball Valves Shop Now

What Is a 3-Way Ball Valve?

3 way ball valves are ball valves with three ports, instead of the usual two ports. Three way ball valves are suitable for mixing, diverting, selection and shutoff applications. 3 way valves can often take the place of two separate valves, providing a cost effective valve solution. The main types of 3-way ball valves are L-port and T-port, which describe the shape of the 'bore' or 'cavity' within the ball. This governs the flow control capabilities and flow patterns through each type of ball valve.

How Do 3-Way Ball Valves Work?

A 3 way ball valve is designed with three ports that allow operators to control and redirect the flow direction of liquids or gases. Inside the valve body, a rotating ball with a bore channels the media toward different outlets depending on the handle or actuator position. This configuration enables both diverting and mixing functions, making it more versatile than standard two-way ball valves.

By turning the handle 90 or 180 degrees, users can select which inlet and outlet ports are open, creating distinct flow patterns. For example, one position may allow one inlet to direct flow toward two outlets, while another position isolates the flow to a single path. These simple yet effective port designs help streamline piping systems, reduce the number of components, and ensure reliable control in industrial applications.

3-Way Ball Valve Designs

Three way valves are designed to mix, divert or select fluid streams, or direct them to relevant process equipment. As their name suggests, 3-way ball valves feature three ports, which may be connected to pipes, fittings or other equipment. Connections are typically threaded, but may also be flanged or welded, to suit the application.

Three way ball valves are available in the following categories:

Mixing Valves: Combines two inlet fluid streams into a single outlet stream.

Diverting Valves: Diverts a single inlet fluid stream to either one of two outlet ports.

Selecting Valves: Selects one of two inlet fluid streams, and moves the selected stream through the outlet port.

3-way valves may be operated manually with a lever, which rotates through a quarter turn (90 degrees) or half turn (180 degrees) to move the valve to the desired position. Three way ball valves may also be controlled using valve actuators, which allow for automated operation and remote control.

Flow Patterns in Three-Way Ball Valves: L-Port vs. T-Port

Three way ball valves are often categorized by the valve internal flow path, which is essentially the shape of the opening in the valve's ball element, which governs the path that fluid flows. ValveMan offers a variety of port designs to fit simple or complex configurations.

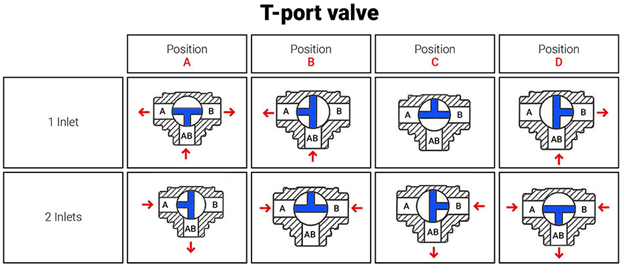

T-Port Ball Valves

T ported 3-way ball valves feature a T-pattern construction, providing one inlet and two outlets. T port ball valves provide complex flow control, including flow splitting, flow mixing, flow diverting or selecting functionality. The image below (from pumpsandsystems.com) provides a visual representation of a T-ported three way ball valve's flow capability.

T-port valves always have a potential fluid path regardless of valve closure setting, meaning that they can never be fully closed.

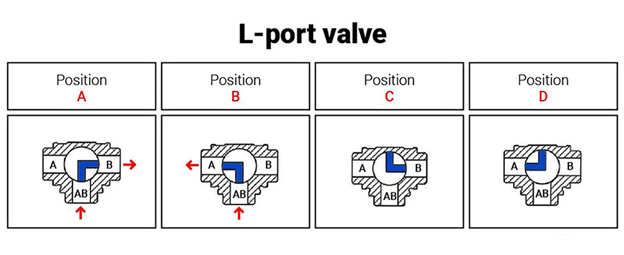

L-Port Ball Valves

L ported 3-way ball valves are valves with an L-shaped bore through the ball. L port ball valves are used for diverting and selecting applications, but cannot operate as mixing valves. They feature two 'open' settings, which directs fluid flow to the right or left. The image below (from pumpsandsystems.com) provides a visual representation of a L-ported three way ball valve's flow path.

Available Materials

When selecting a three way ball valve, the choice of material plays a major role in performance, durability, and compatibility with different media. At ValveMan, our valves are available in stainless steel, lead-free brass, and bronze to cover a wide range of service needs.

Stainless Steel

For demanding industrial applications, steel three way valves provide excellent strength and corrosion resistance. A full port stainless design ensures unrestricted flow, while a robust stem and precision machining help resist long-term wear. These valves are ideal for chemical, high-pressure, and harsh environment systems.

Lead-Free Brass

Our brass three way valves combine reliability with cost-effectiveness. The lead-free brass construction meets safety standards for potable water and food-grade use, while still delivering the versatility needed across residential and light industrial systems. A full port build allows efficient flow, and the smooth operation of the handle makes them easy to control.

Bronze

Bronze valves offer a balance between the durability of steel and the accessibility of brass. Bronze three way ball valves handle a wide range of service applications and maintain solid resistance to corrosion. In many cases, choosing bronze can mean eliminating the need for multiple two valves, since one high-quality bronze valve can perform across different systems.

By understanding the properties of each material, you can match your valve selection to the exact demands of your system. Whether you need the rugged performance of stainless, the safety of lead-free brass, or the proven reliability of bronze, ValveMan provides options designed to last.

Applications of 3-Way Valves

Because 3-way ball valves are reliable, user-friendly and fulfill a number of process functions, they are commonly found in industrial settings. Three-way ball valves offer a simple, economic means of providing shut-off and flow direction control within a single valve body, and are versatile enough for use in many applications, including:

- Oil, gas and petrochemicals

- Water and waste water systems

- Food and beverage industries

- Heating, ventilation and air conditioning (HVAC)

Three way ball valves are used in applications with more than one process fluid, or to divert fluid in two different directions. Each of the three ports are assigned as inlets and outlets, depending on the flow direction. Hence, a three way valve may have one outlet and two inlets, or one inlet and two outlets.

Three way ball valves have three ports and can be manually operated with a lever, or automated with an electric or pneumatic actuator. Three way ball valves can do so many things, like:

- Shut off flow

- Switch flow between two sources

- Combine flow from two sources

- Alternate flow between two destinations

- Divert flow from one source to another destination

- Split flow from one source to two destinations

888-825-8800

888-825-8800