Manual Gate Valves

Manual Gate Valves

Shop Manual Gate Valves Shop Now

Knife Gate Valves

Knife Gate Valves

Shop Knife Gate Valves Shop Now

Key Features of Our Gate Valves

- Full Port Design: Reduces pressure drop and maximizes flow rate

- Visual Indication of Valve Position: Ideal for precise fluid control

- Rising and Non Rising Stem Models: For systems with varying vertical space requirements

- Stainless Steel Options: Corrosion-resistant and built for harsh environments

- Flanged and Threaded Ends: Flexible installation in new or existing piping systems

- Cast Iron, Bronze, and Stainless Valve Bodies: Available in multiple material configurations

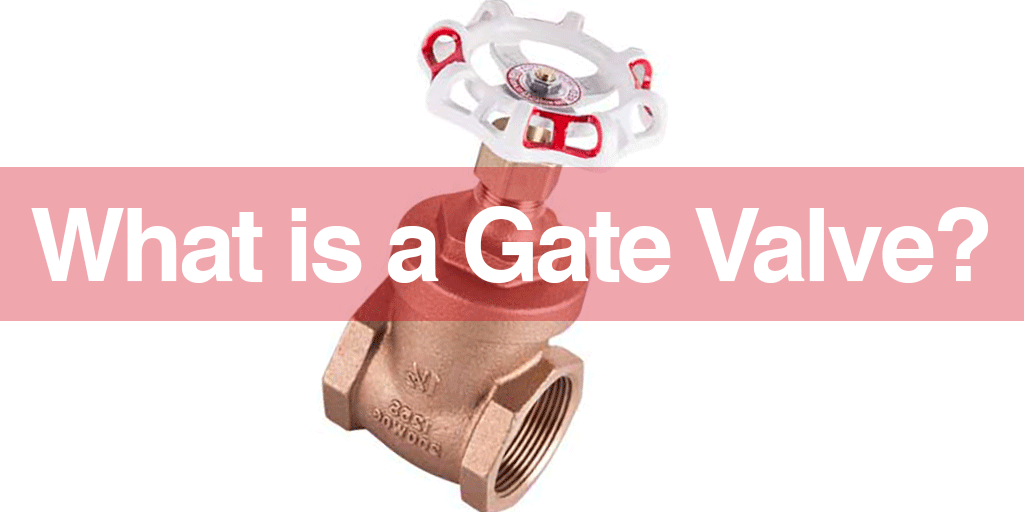

A gate valve is a linear motion valve that uses a wedge-shaped gate to stop or allow the flow of fluid. When fully open, gate valves provide a straight-through flow path with minimal restriction, making them ideal for systems where flow needs to change evenly with minimal obstruction. The gate moves perpendicular to the flow path, which allows for tight shutoff when closed.

Types of Gate Valves Available

Manual Gate Valves

Manual gate valves are among the most common valve types used for isolating fluid flow in both commercial and industrial applications. These valves are designed to operate via a handwheel or operating nut, providing precise control over the valve position.

Our manual gate valves feature rugged bonnet constructions for leak-tight performance and are available in flanged or threaded end connections for easy integration into new or existing piping systems. Depending on your installation needs, you can choose between rising stem and non rising stem models.

Manual gate valves are typically used in clean flow paths, where minimal obstruction and consistent flow rate are essential. A properly selected manual gate valve offers excellent durability and optimal performance when fully open or fully closed.

Knife Gate Valves

Knife gate valves are engineered for tough applications involving viscous media, slurries, or solids-laden fluid. These valves feature a sharpened gate that can cut through thick material while maintaining a tight seal.

Unlike traditional gate valves that use a wedge design, knife gate valves often rely on a parallel gate and seat arrangement to ensure smooth lifting and closure without binding. This design reduces wear and enhances cycle life in abrasive environments.

Our knife gate valves are available in flanged body styles and can be fitted with manual or automated actuators depending on your system’s requirements.

Gate Valves for Steam Systems

Steam gate valves must withstand high temperatures, fluctuating pressures, and potentially corrosive condensate. At ValveMan, we offer a variety of gate valves specifically rated for use in steam distribution, boiler systems, and high-pressure industrial applications.

For steam service, we recommend the following body materials:

- 316 Stainless Steel – Known for excellent heat resistance and corrosion protection in saturated or superheated steam environments.

- Forged Steel – Offers high tensile strength and durability, making it ideal for high-pressure steam lines and thermal cycling.

- Forged Carbon Steel – A rugged option for steam systems that operate under extreme pressure conditions.

All of our steam-compatible valves are available with rising stem or non rising stem configurations, flanged or threaded ends, and feature robust bonnet designs for leak-free performance. When fully open, these valves provide a straight-through flow path, minimizing turbulence and pressure loss in steam pipelines.

Gate Valves for Water Systems

Water systems require valves that offer corrosion resistance, low maintenance, and dependable shutoff performance. Our gate valves are well-suited for municipal water supply, building plumbing systems, and industrial water circulation applications.

For water service, we recommend the following body materials:

- Lead-Free Brass – Ideal for potable water systems and compliant with national drinking water safety standards.

- Cast Steel – Reliable for general water flow control in commercial systems.

- 316 Stainless Steel – A premium choice where long-term corrosion resistance is a priority, such as in coastal or industrial environments.

We offer gate valves with a variety of end connections, including threaded (NPT), flanged, and socket weld. Both rising stem and non rising stem models are available, allowing you to choose the best option for your installation’s vertical space and access needs.

Gate Valve Materials and Configurations

Selecting the right gate valve starts with understanding your system’s requirements for pressure, temperature, and fluid compatibility. At ValveMan, we offer a wide range of body materials and end connections to suit virtually any application, from water systems to steam and corrosive fluid flow environments.

Body Materials

- Cast Steel – A durable and cost-effective material suitable for general-purpose industrial use where moderate corrosion resistance is acceptable.

- Forged Steel – Stronger than cast steel and ideal for high-pressure systems requiring exceptional mechanical strength and reliability.

- Lead-Free Brass – Commonly used in potable water systems and light-duty applications where compliance with drinking water standards is required.

- 316 Stainless Steel – Offers excellent resistance to corrosion, chemicals, oil, and high-temperature fluid flow. Suitable for steam and aggressive media.

- 316L Stainless Steel – A low-carbon stainless option that provides superior weldability and corrosion resistance, particularly in sanitary or high-purity environments.

- Forged 316L Stainless Steel – Combines the corrosion resistance of 316L with the added strength and durability of a forged design.

- Forged Carbon Steel Body – Built for high-pressure systems and heavy-duty industrial applications requiring reliable long-term performance.

End Connections

- Threaded (NPT) – Simple to install and service, threaded valves are often used in smaller pipe systems and tight spaces.

- 150# Flange – The most widely used flanged connection, ideal for moderate-pressure systems across commercial and industrial applications.

- 300# Flange – Designed for higher-pressure environments where a secure, bolted seal is critical for safety and performance.

- 600# Flange – A heavy-duty flanged option suited for high-pressure steam, oil, or corrosive fluid systems.

- Socket Weld – Allows for strong, permanent connections in high-pressure piping systems, commonly used in compact installations.

- Solder – Used primarily in small-diameter copper piping systems for residential or light commercial use, offering quick and effective installation.

Each valve body is built for long-lasting performance, with durable components like the bonnet, gate faces, and operating nut ensuring smooth operation over time.

ValveMan: Your Gate Valve Distributor

As a trusted gate valve distributor, ValveMan serves industries ranging from manufacturing and energy to municipal water systems. Our extensive inventory and in-depth technical knowledge make us the preferred choice for engineers, contractors, and procurement managers across the country.

Our gate valves are designed for systems where flow must be reliably started or stopped without turbulence or rapid pressure changes. When fully open, they provide minimal obstruction, supporting a consistent flow path and stable fluid flow.

Frequently Asked Questions

What is a gate valve used for?

Gate valves are used to start or stop the flow of fluid in a pipeline. They are ideal for isolation applications where the valve will either be fully open or fully closed.

What is a gate valve?

A gate valve is a type of valve that uses a flat or wedge-shaped gate to control the flow of fluid. When opened, it provides a straight path with minimal resistance.

What happens when a gate valve goes bad?

A faulty gate valve may leak, fail to close properly, or get stuck due to debris, worn gate faces, or damaged stem travel components.

What is a water gate valve?

A water gate valve is used in plumbing and municipal water systems to control the flow of water, typically featuring a rising stem and bronze or cast iron valve body.

Which is better: ball valve or gate valve for water main?

Ball valves are better for quick shutoff, while gate valves are ideal for gradual flow control and less frequent operation in large-diameter water mains.

What is the disadvantage of using a gate valve?

Gate valves are not designed for throttling and may wear prematurely if used to regulate flow rather than isolate it.

Are gate valves good for steam?

Yes, especially stainless steel or cast steel gate valves with rising stems, which can withstand the high temperatures and pressures of steam systems.

What valves are suitable for steam?

Gate valves, globe valves, and pressure-seal valves are all suitable for steam, depending on the system pressure and control needs.

What is a stem gate valve?

A stem gate valve refers to whether the valve uses a rising or non rising stem to control the movement of the gate.

What is a rising stem gate valve?

A rising stem gate valve is designed so that the stem visibly moves upward as the valve opens, providing a clear visual indication of the valve position. This makes it easy to confirm whether the valve is fully open or closed. Rising stem models are commonly used in steam and water systems where monitoring valve status is important.

What is a non rising stem gate valve?

A non rising stem gate valve is ideal for tight installations with limited vertical space. In this design, the stem remains stationary while the gate moves internally to open or close the valve. These valves offer the same shutoff performance as rising stem models but with a more compact profile.

What are the typical gate valve configurations?

The most typical gate valve configurations include solid wedge and flexible wedge designs. Solid wedge valves are well-suited for general-purpose use, while flexible wedge designs perform better under variable pressure and temperature conditions. Our team can help you choose the right wedge style for your system to ensure optimal performance.

Which is better: gate valve or globe valve for steam?

Globe valves offer better throttling control, but gate valves are better suited for full shutoff in high-pressure steam lines.

888-825-8800

888-825-8800