2-Way Ball Valves

2-Way Ball Valves

Shop 2-Way Ball Valves Shop Now

3-Way Ball Valves

3-Way Ball Valves

Shop 3-Way Ball Valves Shop Now

Butterfly Valves

Industrial Butterfly Valves

Shop Industrial Butterfly Valves Shop Now

Check Valves

Industrial Check Valves

Shop Industrial Check Valves Shop Now

Steam Traps

Steam Traps

Shop Steam Traps Shop Now

Solenoid Valves

Electric Solenoid Valves

Shop Electric Solenoid Valves Shop Now

Regulators

Pressure Regulators

Shop Pressure Regulators Shop Now

Control Valves

Control Valves

Shop Control Valves Shop Now

Gate Valves

Gate Valves

Shop Gate Valves Shop Now

Needle Valves

Needle Valves

Shop Needle Valves Shop Now

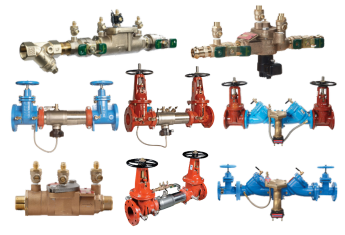

Backflow Preventors

Backflow Preventers

Shop Backflow Preventers Shop Now

Air Filter-Regulator-Lubricators (FRLs)

Air Filter Regulator Lubricators (FRLs)

Shop Air Filter Regulator Lubricators (FRLs) Shop Now

Angle Seat Valves

Angle Seat Valves

Shop Angle Seat Valves Shop Now

Diaphragm Valves

Diaphragm Valves

Shop Diaphragm Valves Shop Now

Plug Valves

Plug Valves

Shop Plug Valves Shop Now

Globe Valves

Globe Valves

Shop Globe Valves Shop Now

Block and Bleed Valves

Block And Bleed Valves

Shop Block And Bleed Valves Shop Now

Safety Relief Valve

Safety Relief Valve

Shop Safety Relief Valve Shop Now

Actuators & Accessories

Valve Actuators

Shop Valve Actuators Shop NowSolve Your Flow Control Challenges with the Right Valves

Many homes, businesses and industrial facilities face valve and flow related challenges, including incorrect system pressure, low or irregular flow, and unexpected downtime due to valve, equipment or pipe failures. Whether you’re dealing with equipment damage due to backflow, a pressure relief problem, or inadequate flow control, selecting the proper valves can help prevent these issues (and many more), while ensuring reliable, efficient operation across your fluid systems.

Why Choose Professional Valve Solutions?

Ensure that your most critical facilities and process lines use valve technology that is engineered for maximum performance, durability and reliability. Professional valve solutions give you peace of mind with:

Reduced System Downtime: Quality isolation and emergency shutdown valves provide reliability in critical applications, preventing unexpected shutdowns that hurt your bottom line.

Enhanced Safety: Pressure relief valves prevent dangerous overpressure conditions, while check valves prevent equipment damage due to backflow.

Precise Flow Control: Control valves such as globe valves, needle valves and pinch valves offer accurate flow regulation, ensuring stable operation regardless of pressure variations.

Lower Operating Costs: Properly sized valves help reduce energy consumption. Valves with optimized internal geometry improve flow patterns, reduce pressure losses and improve efficiency across your system.

Extended Equipment Life: Robust design and corrosion resistant materials like stainless steel help valves achieve extended service life. Specialized materials are also better at handling handle extreme temperatures and aggressive chemicals.

What Makes Different Types of Valves Special?

Understanding the features and characteristics of different valve types helps you select a product that is the best fit for your application. Here are some examples.

Ball Valves

Quarter turn operation provides quick and simple operation, ideal for emergency closure and use as shut-off valves. Floating ball valves are suited to low pressure isolation, trunnion mounted ball valves are more reliable for high pressure systems, and segmented ball valves (also called V-port ball valves) may be used for moderate flow control.

Butterfly Valves

Their compact design saves space compared to bulkier isolation valves, such as gate valves and ball valves. Butterfly valves are available in wafer, lugged and flanged connections, and are cost effective for isolation in large diameter piping (from 8” to 120”). As the valve disc remains in the flow path even when the valve is fully open, butterfly valves have a larger pressure drop across the valve when compared to full-port isolation valves.

Globe Valves

Globe valves are a type of control valve, which means they are suited to flow throttling and flow regulation. They are essential for applications such as process control, which requires accurate flow adjustment over a broad range of fluid flows.

Check Valves

These valves prevent backflow, by allowing flow in one direction only, and closing when flow begins to reverse. This protects equipment such as pumps, prevents tanks from draining, and can even prevent contamination. Check valves are also known as non-return and reflux valves, and are available in many designs including swing check valves, lift check valves, nozzle check valves and ball check valves.

Gate Valves

Commonly used as shut off and isolation valves, allowing sections of pipeline or equipment to be isolated for repairs and maintenance. Gate valves use linear motion to raise or lower the valve disc, starting and stopping fluid flow. Gate valve designs include rising and non-rising stem, outside screw and yoke (OS&Y), resilient seal and wedge gate. Gate valves provide a full bore flow path which minimizes pressure drop when the valves are fully open.

Needle Valves

Another type of control valve, needle valves are suited to smaller diameter piping systems. Needle valves provide fine, accurate flow control, and are suited to applications like fluid metering or dosing.

Relief Valves

Relief valves come in different forms, such as pressure relief, temperature relief and vacuum relief. Broadly classed as safety relief valves, these valves operate automatically to relieve excess pressure, preventing system damage or failure.

Valve Actuator Types

Modern plant automation and control systems require robust actuator solutions to reliably operate valves. The most common valve actuators include:

Electric Actuators: These provide position control with motor-driven linear or rotary drives. Most electric actuators require a power source, and may integrate instrumentation feedback for precision control.

Pneumatic Actuators: Compressed air operates pneumatic actuators through pistons or diaphragms. Double acting pneumatic actuators use air pressure to operate in both directions, while single acting pneumatic actuators use air in one direction only, together with a with spring return feature.

Hydraulic Actuators: Applications commonly use hydraulic actuation systems where high forces, high torque, heavy loads or constant power. Hydraulic cylinders can provide powerful linear motion for large gate valves in high-pressure applications. They may also be used for counterweight or damping systems in check valves.

Manual Valves: Hand wheels and levers allow direct manual operation, for applications where automation isn’t required. These work by applying a direct mechanical force to the valve stem. Gearing is used to allow easier operation of large valves, or for applications where high torque is needed.

Valve Actuator Applications

Valve actuators and accessories are used for a range of operations in manufacturing and processing, the utility sector and power generation industries.

Process Control: Electric actuators with position and control system feedback provide precise valve position and control in chemical processing and refineries. Limit switches detect valve travel and position for fully automated systems.

Emergency Shutdown: Rapid, reliable shutoff is needed when safety systems detect dangerous conditions. Emergency shutdown valves (known as ESD valves for short) typically operate using fail-safe mechanisms, typically failing to a closed state.

Remote Operation: Actuators allow valve control from remote locations, essential for systems where manual operation isn’t practical or safe. Manual overrides may be activated when needed.

Flow Modulation: Linear actuators provide smooth control valve operation for processes requiring constant flow rate adjustment. Actuator motion characteristics can be defined to match any specific process requirements.

Get Your Valve and Actuator Solutions Today

Whether you're looking for valve selection advice, or need to retrofit an existing valve with an actuator, our valve experts provide complete solutions tailored to your specific application requirements. Contact ValveMan today for valve spec assistance, sizing guidance, material selection advice, and application engineering support. After all, we've been doing this for over 60 years!

888-825-8800

888-825-8800