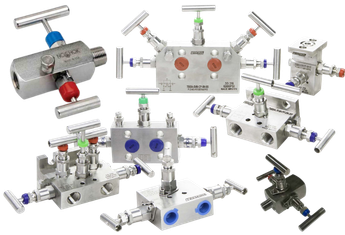

Block and Bleed Valves

Block and Bleed Valves

Shop Block and Bleed Valves Shop Now

2-Way Needle Valves

2-Way Needle Valves

Shop 2-Way Needle Valves Shop Now

Manifolds

Valve Manifolds

Shop Valve Manifolds Shop Now

The major advantage of a needle valve is that it facilitates the gradual slowing and/or halting of a media, and that this operation can be adjusted by hand in finite movements. This is why needle valves typically use a T-type handle, or one that is like a wheel, checkered around the edges for a sure, comfortable grip. No other style of valve offers such precision tuning.

Fine Tuning

A common place where you might observe the use of needle valves is in a laboratory, protecting sensitive and delicate gauges from sudden media surges which could result in damage. This is a situation where the media flow must be adjusted manually, and gradually, where only a small rate of flow is desired. However, the fine tuning that only a needle valve can provide is demonstrated in several industries, including but not limited to, zoological sciences, vacuum systems, gas and liquid dispensation, power generation, and any other industry in which precise control within a low flow rate is desired.

Utilizing what is essentially a tapered spindle, a needle valve works on the principle of the Vernier effect, just like on a micrometer. In the needle valve's case, it is the difference in diameter between the needle and the seat, or the ratio between the needle's length and diameter. Precision control is a direct result, as the axial movement in either direction requires little effort. In simpler terms, the needle has a tapered point that restricts the flow of media movement, and doubling as the valve stem, can be adjusted in small increments to either restrict or permit flow. If you've ever used a spray gun for painting, you've undoubtedly adjusted its spray pattern with similar screws.

Needle valves should be used anywhere delicate control is concerned, wherever exacting adjustments of flow are needed, and whenever the flow of a particular gas or liquid must be brought to a gradual stop. Often referred to as a throttling ability, needle valves are capable of much more than just opening or closing, and therefor are perfect for any application warrants intermittent control, and determinate control.

Restrictions

Like every other valve, needle valves do have limitations. While they are used in a variety of industries and in numerous applications, they should not be used for media that is viscous, nor should they be used for slurry (as in anything insoluble, like cement) dispensation. If you've found this information enjoyable, and would like to read another article, you might like Bonomi Solenoid Valves.

Click here to view our full selection of valve categories.

888-825-8800

888-825-8800