Globe Valve vs Ball Valve Comparison Guide | ValveMan

Posted by Russ Bailey on Jun 18th 2025

Valves are widely used in industrial and manufacturing facilities, but they’re also used in utilities, commercial and residential settings. You’ll find valves as close as your home or car, and you’ll also find them as far away as the international space station! There are many, many types of valves, with two common types found in service being ball valves and globe valves. A common question is which valve to choose between the two. To answer this question, let’s take a detailed look at the ins-and-outs of globe valves and ball valves.

What Is A Globe Valve?

A globe valve is a type of control valve used to regulate fluid flow in a pipeline. It is a linear motion valve that regulates or stops the flow of fluid by moving the valve plug up and down, that is between open and closed position, in relation to the valve seat.

Globe valves are primarily used to control the flow of liquids and gases in industrial facilities, power generation and water supply systems. Globe valves are suited to flow control and throttling applications, and may also be used to shut-off flow completely.

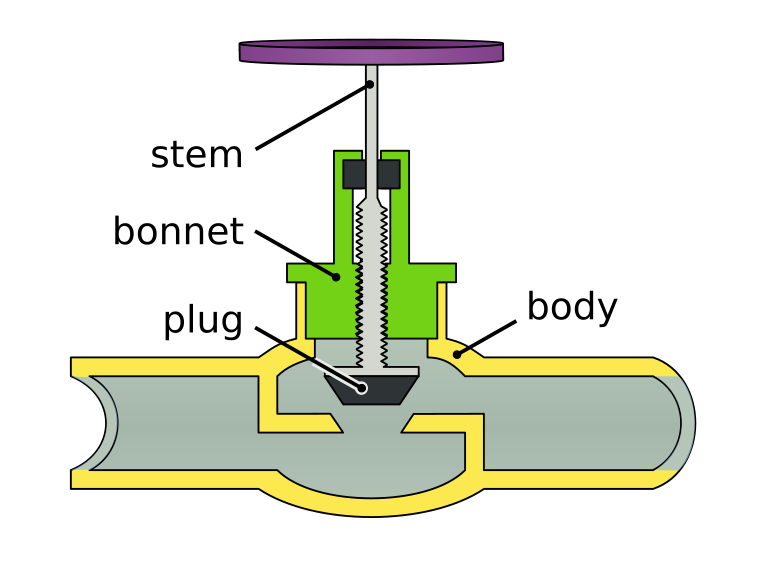

Modern globe valves typically comprise a valve body with a spherical or 'globe' shape, a bonnet which seals the valve body and houses the stem, and a valve plug (or disk) at the end of the stem, which moves up and down as the valve is actuated, and seals against the valve seat. Globe valves are available in different design and material configurations, to meet project and application specific requirements. Globe valves are commonly found in oil and gas, power generation, chemical processing, HVAC and plumbing systems.

What Is a Ball Valve?

A ball valve is a rotary valve that regulates fluid flow by turning a ball with a hollow bore through its centre, into and out of the flow path. Ball valves can effectively start or stop fluid flow with a quarter-turn or 90 degree rotation.

Ball valves comprise a valve body to house the valve internals, ball element for flow regulation, seats for effective sealing, and valve stem which connects the ball and actuator. Ball valves are known for their durability, reliability and simplicity, and are suited to frequent operation. Ball valves are a good choice for shut-off applications and may be used for moderate flow control, however, they lack precise flow control in throttling applications. Like gate valves, ball valve designs have evolved over time, with many configurations and specifications available, to suit a myriad of applications, ranging from superheated gases to cryogenic liquids, and everything in between.

Comparing Globe Valves and Ball Valves

Now that you’re familiar with globe valve and ball valve basics, let’s look at each valve’s functionality and identify some of the key differences between these valve types.

Flow Control Mechanics

Both ball valves and globe valves regulate fluid flow through a pipe, but they do so using different mechanisms. Globe valves control fluid flow through the linear movement of the valve plug, which is moved by a threaded stem, to precisely adjust the size of the annular opening between the plug and seat. As the disc is raised, the opening for the fluid increases, allowing more flow; conversely, as it is lowered, the opening narrows, restricting flow. This allows for fine-tuning of flow through the valve, making globe valves ideal for applications requiring precise flow control. Depending on plug design, globe valves typically provide linear or equal percentage flow control characteristics.

Ball valves make use of a ball element with a hole through its center to control the flow of fluids. The ball may be rotated to align the hole with the flow passage, allowing flow through the valve. Ball valves are typically used as isolation or shut-off valves, completely starting or stopping flow. Ball valves provide a quick shut off, with a quarter-turn of the valve handle moving the valve from fully open to fully closed position. Ball valves with custom notched balls or seats, referred to as segmented or v-notch ball valves, are suited to moderate flow control applications.

Valve Flow Direction

Most ball valves can be used for bi-directional flow applications, while globe valves are only suited to uni-directional flow. Standard ball valves are typically supplied with double-end sealing designs, however some specialized ball valve designs may be uni-directional. Uni-directional valves often have a flow direction indicator (such as a flow arrow) on the valve body, to indicate the correct valve orientation.

Valve Seal Capacity

Globe valves and ball valves are available in both soft and metal sealing configurations. Soft seated valves typically provide a 100% leak-tight seal, however these valves are not suited to extreme pressures and temperatures. They are also not suited to abrasive or ‘dirty’ fluids, which may damage the seats. Metal seated valves are suited to high pressure and high temperature applications, however there is typically an acceptable leakage rate allowed for metal seated valves. Metal seated valves generally offer superior durability and longevity in harsh environments.

Both ball valves and globe valves are available in a range of soft and metallic sealing materials, to suit project and application specific requirements.

Valve Design and Construction Differences

Globe valves are available in three main body designs. These are wye pattern, tee pattern (also called Z-pattern), and angle pattern. Angle pattern valves modify the flow path by 90 degrees, eliminating the need for a separate elbow in the pipework. Z-type globe valve designs are common, however they do have a large pressure drop across the valve. Y-pattern valves provide an angled internal flow path, reducing pressure drop across the valve.

Globe valves may also be distinguished by the type of disc element (plug, tapered plug, ball, or composite disc), the type of bonnet and type of stem. Globe valves are generally bulkier, taking up more space than similar sized ball valves.

There are many types of ball valves available, with some design distinctions being full port or reduced port configuration, floating ball or trunnion mounted, single or split body types, two-way, three-way or multi-port connections, and segmented or V-port balls for control applications. Ball valves take up relatively less installation space than globe valves. Full port ball valves offer minimal pressure drop across the valve.

Valve Material

Both globe valves and ball valves are available in a range of materials. Standard materials for these valves include cast iron, brass, bronze, ductile iron and cast steel. Specialized valves may be made from stainless steel, titanium or other ‘exotic’ metals and alloys. Plastic is also used as a material option for residential, commercial and irrigation valves.

Similar to the valve body, trim for globe valves and ball valves may be selected from a broad range of metallic and non-metallic materials. These include bronze, brass, cast steel and stainless steel, or plastic options such as NBR, EPDM, Viton and PTFE. Valve trim and internal components must be carefully selected, taking into account the nature of the fluid and operating requirements. Aside from factors such as operating pressure and temperature ranges, phenomena such as pressure surges, water hammer, cyclic loading, vibrations, cavitation, corrosion and abrasion should not be neglected when specifying valve materials.

Globe Valve and Ball Valve Applications

Globe valves are control valves, meaning they are primarily used for flow control applications, while ball valves are suited to fluid shut-off and isolation applications. On the other hand, globe valves may also be used to shut-off flow, and ball valves may also be sued for moderate flow control, provided a segmented or v-port ball valve is used.

Both valve types find use in a broad range of market sectors and industries, including manufacturing, oil and gas, chemical processing, pharmaceuticals, power generation, HVAC and water systems.

Are Ball Valves Better Than Globe Valves?

There is often debate in the valve world regarding the merits of different valve types - a common topic is whether ball valves or globe valves are better. The simple answer is that there is no right answer! Each type of valve has advantages and disadvantages, so the best valve must be assessed on a case-by-case basis. Below are some factors to consider when comparing globe valves and ball valves for a particular project.

- Function: A ball valve is a quarter-turn valve that uses a hollow ball to control fluid flow. The ball is connected to a lever or handle to open and close the valve. On the other hand, a globe valve is a linear motion control valve that uses a plug type element which slides up and down to control liquid or gas flow.

- Cost: Ball valves are typically less expensive than globe valves, especially when comparing smaller valve sizes.

- Durability: Both ball valves and globe valves are considered durable. Valve durability is also largely dependent on the valve spec, installation and operating conditions, and valve operation and maintenance.

- Application: Ball valves are typically better for applications where frequent, quick operation is required for on-off duty. Globe valves are suited to flow control and throttling operations.

- Sealing: Both ball valves and globe valves are capable of leak-tight sealing. However, ball valves generally exhibit superior sealing performance than globe, which are typically dedicated and assessed for flow control and not flow shut-off capability.

- Opening and closing speed: Due to its quarter turn operation, ball valves are suitable for applications needing fast operation. To move a globe valve from fully open to closed, the valve handwheel must be turned many times.

Valve Selection: Globe Valve Vs Ball Valve

As we’ve already discussed, there are a number of factors to consider when choosing between ball valves and globe valves. Here are some critical selection criteria:

- Pressure: Both ball and globe valves can handle high pressures, but metallic designs are inherently better suited for high-pressure applications.

- Temperature: Both ball valves and globe valves can handle high temperature applications, provided their trim and seal materials are specified correctly.

- Flow: In general, ball valves have a higher flow capacity than globe valves, due to their less restrictive flow path, with low pressure drop across the valve.

- Ergonomics: Ball valves are less bulky and easier to operate than globe valves.

Based on the above criteria, one would typically recommend ball valves for shut-off and isolation applications, where space is limited, or where quick operation is required. Globe valves are recommended for flow control applications.

Need More Information?

If you’re still not sure which valve is the best fit for your project, get in touch with ValveMan right away. With technical expertise and reliable customer support a hallmark of our 60 year legacy, we’ll definitely be able to guide you to not just a valve, but the best valve solution for your needs.

888-825-8800

888-825-8800