Pneumatic Actuators Valve Types

Posted by Gilbert Welsford, Jr on Dec 16th 2025

Have you ever stopped to think about what makes an automated assembly line push, pull, lift, and rotate parts with such perfect timing?

- 3/2 (3-way, 2-position): best for single-acting actuators (pressurize in one position, vent in the other).

- 5/2 (5-way, 2-position): best for double-acting actuators (alternates air between two working ports).

- 5/3 (5-way, 3-position): best when you need a neutral/mid state (closed-center, exhaust-center, or pressure-center).

It’s pneumatics: the power of compressed air. And at the core of any air-powered system are two key elements: actuators, which do the work, and directional control valves, which stop, start, or redirect air flow.

This blog post is going to explore pneumatic control valves, starting with a review of pneumatic actuators and providing an in-depth look at directional control valves. Be prepared to learn the secrets of pneumatic control!

Pneumatic Actuators

There are three types of air-controlled actuators: linear, rotary, and specialty. Let’s review them.

Linear Motion Actuators

Linear motion actuators are for clamping, lifting, pulling, and pushing. This type of actuator uses a traditional piston-style cylinder, in which compressed air acts on a piston within a tube to move a rod linearly. Rodless cylinders are a more compact option for long strokes, while diaphragm actuators don't use a rigid piston and provide shorter, more sensitive linear movement.

The image below is a STC 2KS Series Single Acting- Air Actuated 2-way angle seat valve. It uses direct piston actuation with a spring-loaded stem and is made from 316 stainless steel with PTFE seals.

Rotary Motion Actuators

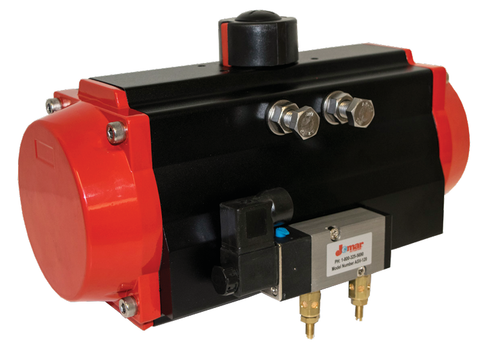

Rotary motion actuators convert compressed air into rotating or oscillating motion. This type of actuator can reorient parts or open/close valves. There are three types: rack and pinion, vane, and scotch yoke. Rack-and-pinion actuators use a straight gear meshed with a pinion to provide consistent torque. Vane actuators utilize a vane within a cylindrical chamber to rotate. They’re known for their compact size and high torque output. Finally, Scotch yoke actuators use a piston to drive a pin within a slotted yoke and are often found in large industrial valves.

An example of a rotary motion actuator is Jomar Valve JV Series of spring return pneumatic actuator ball valves. They're designed for use with quarter-turn ball, butterfly, and plug valves as well as damper applications.

Speciality Motion Actuators

A variety of specialty actuators exist to help achieve more difficult motion tasks, including rotary index tables, escapement mechanisms, and guided actuators. These may be combined to form a more complex mechanism, such as a pneumatic gripper.

Directional Control Valves for Pneumatic Actuators

Pneumatic control valves interact with the pneumatic actuators just discussed. Pneumatic directional control valves are usually categorized based on three key attributes: the number of ports, the number of positions (the ways), and the method used to shift the valve. Some examples include 3/2 way, 5/2 way, and 5/3 way directional control valves, which we’re about to discuss.

3/2-Way Directional Control Valve

A 3/2-way directional control valve has three ports and two positions. The ports are as follows:

- Pressure/Inlet

- Outlet/Working

- Exhaust

These valves are typically used to control a single-acting cylinder actuator. This type of actuator uses air to move in one direction and either gravity or a spring to return. The two positions are (1) to supply air to the actuator and (2) to block the supply and vent the air from the actuator to the exhaust.

The STC 3A110-410 Series pilot-operated air valve shown below is a 3-way, 2-position control valve. It’s made from anodized aluminum with a Buna N seal material, and is also body ported and stackable.

5/2-Way Directional Control Valve

A 5/2-way valve has five ports and two positions. The ports are as follows:

- Pressure/Inlet

- Working Port A

- Exhaust for Port A

- Working Part B

- Exhaust for Port B

The 5/2-way directional control valve controls double-acting cylinders and rotary actuators, both of which require air pressure to move in both directions. The two directions are extend and retract. In position (1), air is supplied to port A while exhausting air from port B in one direction. In position (2) air enters port B while exhausting air from port A; this moves the actuator into its other position.

The STC 4F210 Series foot-operated air valve shown below is a 5-way, 2-position control valve. It is manufactured from anodized aluminum with a Buna N seal material and is engineered only for use with air flow.

5/3-Way Directional Control Valve

The 5/3-way valve has five different ports and three positions. The ports are the same as for the 5/2-way valve. These pneumatic directional control valves support double-acting actuators when a neutral or mid-stroke stop is needed.

In position (1), air is supplied to one side, and the other side is exhausted. In position (2), air is supplied to the second side while the first side is exhausted. Position (3) is the neutral or mid-stop position, which is usually configured as one of the following:

- Closed center, where all ports are blocked and the actuator locks into place

- Exhaust vent, where both vents are exhausted and the actuator floats freely

- Pressure center, where both working parts receive air pressure which balances the forces and holds the actuator against some load

The STC 4H230 Series manual air valve shown below is a 5-way, 3-position control valve. Like the other valves we’ve discussed, it’s also made from anodized aluminum with a BUNA N seal.

Actuation Methods

Directional control valves can also be categorized by how they shift between positions or are actuated. There are solenoid-operated, air-operated, manual, and mechanical.

Electric signals control solenoid-operated directional pneumatic valves. Air-operated control valves depend on compressed air signals to achieve the necessary switching. They’re commonly used in hazardous environments where electricity can pose a danger. There are also manual pneumatic control valves operated by a push button, foot pedal, or lever. Mechanically operated pneumatic control valves are switched by physical contact with a moving part of a machine. Examples of mechanical parts include rollers, plungers, or cams.

Conclusion

Directional control valves provide essential control over the flow of compressed air that’s required to move linear, rotary, and specialty actuators. Whether you need the simple on/off control of a 3/2-way valve for a single-acting cylinder, the extend/retract function of a 5/2-way valve for a double-acting actuator, or the nuanced mid-stop capability of a 5/3-way valve, selecting the correct component is critical for efficiency and precision. Contact us here at ValveMan for help in finding the right pneumatic actuator valve solution for your design!

888-825-8800

888-825-8800