Smart Water Valves: Futuristic Flow Control Technology

Posted by Gilbert Welsford, Jr on Jan 22nd 2026

Leaks can range from annoying to devastating, and the longer they go unaddressed, the more costly the damage will be. Depending on what is being leaked, there can be downtime costs, process disruption, contamination, environmental issues, safety concerns, and even hefty fines.

With modern fluid flow technology, more and more engineers are moving toward smart water shutoff valves that can save you money if (and when) a leak occurs. And these shutoff valves aren’t as complicated as you might think. Because smart water valves are shaping the future of flow control, ValveMan is here to explain how smart shut-off valves work and their role in leak prevention.

Traditional Approaches to Water Shutoff

Let’s talk for a minute about some of the traditional approaches to water shutoff. Historical solutions have relied on mechanical spring-return actuators and fail-safe solenoids. They are normally closed or normally open configurations where a valve is held in its operating position either by pneumatic or electrical force. The moment that force becomes interrupted, a mechanical spring (pre-compressed) drives the valve to its safe state. It’s simple, straightforward, and reliable. But it still leaves a lot to be desired.

While its reliability is high, there is no speed control for a soft close, so the flow is shut off immediately and violently. It isn’t energy-efficient because it's always on, and there’s quite a bit of maintenance due to mechanical wear.

In addition, traditional systems use manual overrides and hardwired interlocks to allow bypassing software control during an emergency. Plants will likely have a panic button or ESD (Emergency Shutdown) system that is isolated from the primary PLC. The goal of this kind of setup is to ensure that, no matter the state of the computer system or network, a human can enact an immediate shutoff.

While this approach is practical and includes key redundancies, there are better approaches.

Smart Water Valves

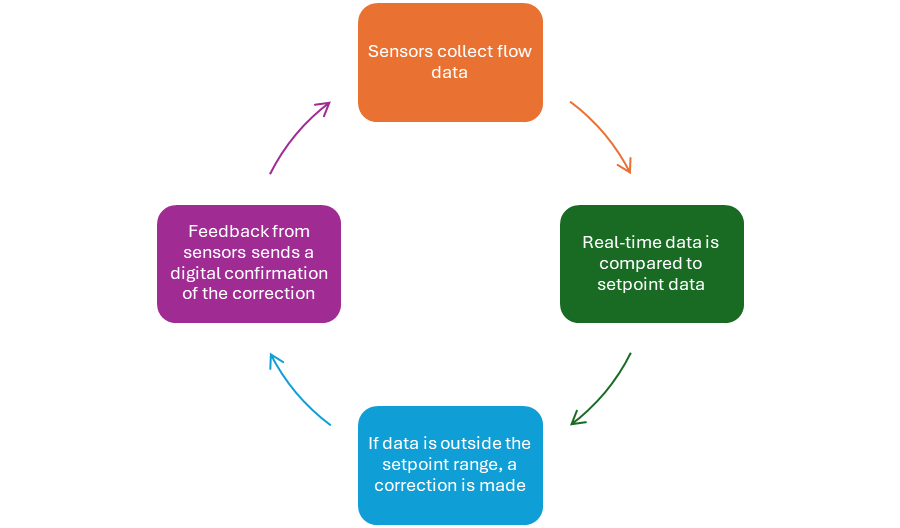

Smart water valves differ from traditional valves because they utilize a feedback loop that doesn’t just close the valve, but ensures the flow is actually cut off and explains why it had to be done.

Sensors collect flow data as well as pressure, temperature, and stem position data, depending on the setup. That real-time data is compared with predetermined setpoint data to determine whether anything is wrong (e.g., a leak, a burst pipe, freezing temperatures, etc.). If any data is outside the setpoint range, a correction is applied to move the valve position. The sensors send a digital confirmation that the move was completed. More real-time data is received, and the feedback loop continues. This is the essence of how a smart valve works. It continuously monitors the pipeline to ensure that leaks are caught quickly.

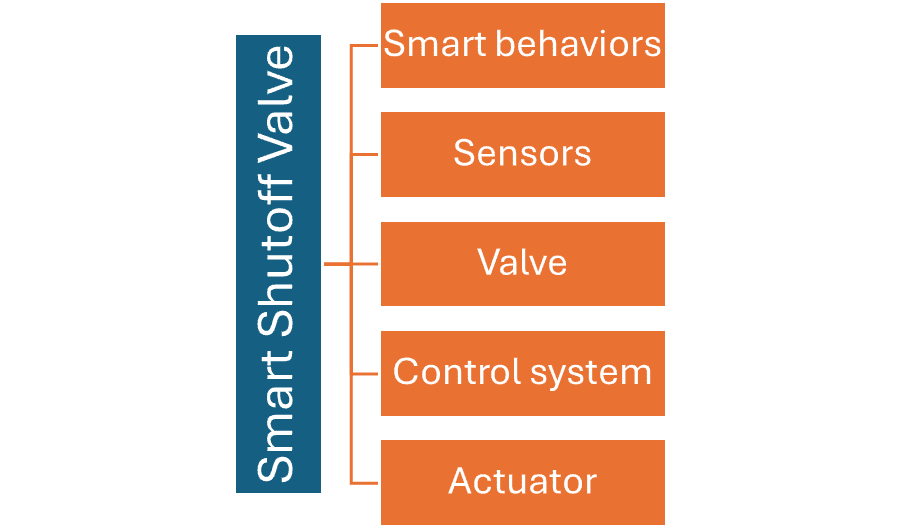

Basic Anatomy of a Smart Shutoff Valve

Now, let’s break down the anatomy of a smart shutoff valve by referencing the image below.

Smart Behaviors

Let’s start off with smart behaviors. An industrial smart shutoff is usually going to implement at least one of these behaviors:

- Leak detection and isolation, which is typically used for unexpected continuous flow, night-flow, or flow with no demand

- Burst/pipe break response, which responds to flow rate spikes, pressure drop, or downstream pressure collapse

- Backflow / reverse flow detection, which verifies the direction of flow

- Process interlock, which initiates shutdown if the tank level is low, the pump trips, or the filter differential pressure is too high.

- Remote emergency stop, which includes a button, SCADA command, or safety system

In addition, most systems also need two modes: automatic mode, which combines rules with thresholds, and a manual or maintenance override mode, which is lockout/tagout friendly.

Sensors

There are several types of sensors that may be utilized in a smart water valve system. Here are some of the most common:

- Flow Meters: detect leaks or abnormal consumption, and are always used

- Pressure Transducers: monitors for pipe bursts or pump failures based on pressure differentials; can be combined with flow meters to detect burst pipes

- Limit Switches: physical sensors that can confirm if the valve is 100% open or closed

- Temperature: temperature readings that can be used to monitor the potential for water freeze issues

Below is an example of a flow meter. In this case, it’s a Tek-Trol Tek-DP 1620A Series cone meter.

Valve

Among the many types of valves used in a smart valve system, common options include solenoid valves, ball valves, and butterfly valves. While solenoid valves are easy to use and work quickly, they often have limitations in size, pressure, and dirt tolerance. They also don’t require a separate actuator. An example is the STC 2DS1500 6” flanged solenoid valve shown below.

Ball valves work great for quick, full shut-off, and they have a low pressure drop and a robust shut-off. While they are extremely durable, ball valves are going to need quite a bit of torque to turn them. A ball valve combined with a pneumatic actuator, the Bonomis 8P0173 series, is shown below.

Another option would be butterfly valves. They are great for large-diameter pipes and are much more compact than ball valves, with lower weight and cost, but they are harder to seal at high pressures. The shutoff is highly dependent on pressure and the valve seat. The image below is a Bonomi ME530S-00 Series, a wafer-style butterfly valve with an electric actuator. It has a cast-iron body and a stainless steel disc.

Actuator

The actuator is what actually turns the valve. There are three actuator options:

- Electric motor actuator: this requires simple wiring and easy telemetry, but won’t close as fast as other options

- Pneumatic actuator: this option is fast and strong and works extremely well for large valves; it does, however, need clean instrument air

- Hydraulic actuator: this option is powerful but is going to be more complex; it's also less common for water shutoff

The image below shows an example of a combined butterfly valve and pneumatic actuator, the CORA CV Series 6" Ultra Sanitary Butterfly Valve.

The image below is an AVCO ACT-PN-CSR052-12 Pneumatic Actuator with an extruded aluminum body and die-cast aluminum end caps. These actuators work well in a variety of applications in the food, pharmaceutical, and chemical industries.

Below is a Jomar Valve AE-180-24VAC electric actuator that includes a manual override and is NEMA 4X rated with an IP67 enclosure. They have a hard anodized aluminum housing with external powder coating for severe duty applications.

Control System

For the control system, you’ll need an industrial controller and a protocol to talk to your network. The most common protocols are Modbus TCP/IP, MQTT over WiFi/Ethernet, or LoRaWAN for long-distance communication.

Fail Position

Another critical aspect of a smart valve is the fail position. In the context of smart and industrial valves, the fail position is the state the valve automatically moves to if it loses its primary power or its control signal. The table below summarizes the options available.

| Goal | Best Fail Position | Logic |

|---|---|---|

| Prevent Flood | Fail Closed (FC) | Stopping the water is the safest default, but it has the potential to disrupt processes |

| Prevent Overheat | Fail Open (FO) | Safer for process continuity but riskier for leaks; often used to keep coolant moving |

| Maintain Pressure | Fail Last (FL) | Used when sudden changes would initiate a water hammer |

| Advanced Control | Fail Preset | Allows a specific "limp home" flow rate. |

Applications of Smart Water Valves

We’ve alluded to the use of smart water valves in industrial settings. There’s also a massive demand for them in other areas, as well. In commercial real estate, a smart water shut-off valve can help prevent devastating water damage on upper floors in hotels or high-rise office buildings.

As data centers move to liquid cooling, a single leak can cause millions of dollars in hardware damage, but smart water valves can quickly isolate a cooling link. Water damage in hospitals can lead to serious safety issues and costly damage, which can be mitigated with a smart valve system.

In municipal water management, cities can use smart valves in their distribution networks to manage water lost to leaks before it reaches the customer, also known as non-revenue water. In the agricultural industry, smart flow control systems help farmers get efficient use out of irrigation water and enable them to release water according to crop needs, instead of timer-based solutions.

Looking Towards the Future

More advanced smart water valves include machine learning. Pattern recognition, which is fundamental to machine learning, can use AI to learn about the normal flow patterns. This allows it to pick up on more issues, like a silent pinhole leak that would otherwise stay within normal setup point ranges but deviates from historical patterns. Historical data can also provide a more detailed analysis of what happened prior to the leak, so it can possibly be prevented in the future.

Conclusion

Leaks are dangerous and costly, but smart water valves have made it possible to confidently address leaks as soon as they happen, and help you understand more about what caused them. Using a feedback loop that involves one or more sensors, a valve, an actuator, and a control system, combined with smart behaviors, might save you thousands of dollars.

Here at ValveMan, we’ve got the sensors, valves, and actuators you need to set up your own smart water shutoff valve. Contact us today and let one of our valve experts work with you to find the smart valve solution that you need, whether it’s a retrofit or a new install.

888-825-8800

888-825-8800