Globe valves are a type of linear motion control valve used for regulating or 'throttling' fluid flow, as well as for stopping and starting flow in a pipe system. Globe valves are ideal for applications that require precise flow control, and may also be used to shut-off flow.

How do Globe Valves Work?

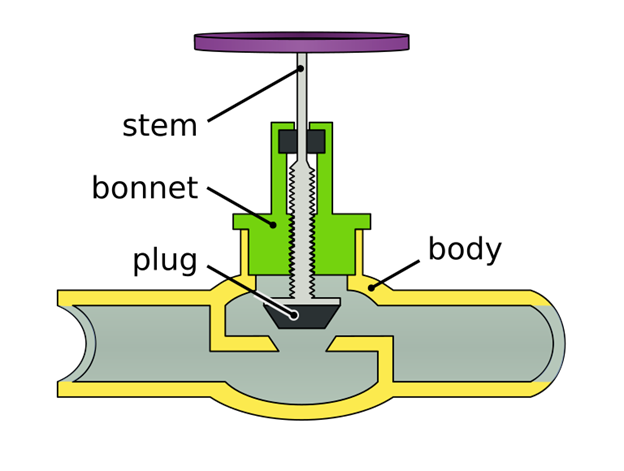

Modern globe valves typically comprise a valve body with a spherical or 'globe' shape, a bonnet which seals the valve body and houses the stem, and a valve plug (or disk) at the end of the stem, which moves up and down as the valve is actuated, and seals against a stationary valve seat.

Globe valves are designed to regulate flow. As the plug is raised or lowered, it changes the size of the opening through the valve, allowing for precise control of the fluid flow rate. Once the disc is seated firmly against the stationary ring seat, it creates a leak tight seal, which minimizes leakage across the fully closed valve.

Globe valves develop a tortuous fluid flow path through the valve body, which creates a relatively high pressure drop across the valve. This energy loss is required to provide the valve's enhanced flow control and throttling capability.

Similar to other linear motion valves, such as gate valves, globe valves have relatively slow operation as multiple turns of the handwheel or actuating device are needed to open or close the valve. On the plus side, this slow valve opening and closure may help to prevent pressure surge or 'water hammer' effects. Globe valve designs are generally bulkier than ball valves and butterfly valves of comparable size.

Globe Valve Designs

Globe valves are available in three main body designs. These are wye pattern, tee pattern (also called Z-pattern), and angle pattern valves.

Angle valves modify the flow path by 90 degrees, with the valve acting as a combined control valve and elbow, eliminating the need for a separate elbow in the pipework.

Z-type globe valve designs are common, where the stem and plug move perpendicular to the pipe axis. This creates a large pressure drop across the valve.

Y-pattern valves provide an angled internal flow path, where the stem and seat positioned at a 45-degree angle to the pipe axis. This creates a straighter flow path and reduces pressure drop across the valve.

Globe valves may be distinguished further by valve size, pressure rating, end connection, port type (full port or reduced port), disc element (plug, tapered plug, ball, or composite disc), bonnet (bolted, welded or threaded), type of stem (rising and non-rising stem, integrated and non-integrated disk, outside screw and yoke - OS&Y), valve trim and material options.

More on globe valve discs

Globe valves are available with different styles of discs. The most common options include:

Plug disc: The plug disc design consists of a solid, tapered disc with a plug-like shape. The plug fits tightly within the valve seat to regulate or block flow. Plug discs are known for their durability and providing reliable, precise flow control over a broad operating range.

Ball disc: The ball disc consists of a spherical ball that aligns with the seating surface to control flow. Ball discs offer smooth operation and are particularly effective in applications requiring quick shutoff capabilities. Ball disc designs are suited to moderate flow control applications.

Composition disc: A composition disc includes a replaceable insert, which is typically made of a softer material like rubber, PTFE or other plastic. This design ensures a tight seal between the disc and seat ring, even if there is sediment or particulate matter in the process fluid.

Globe valves may also be fitted with balanced or unbalanced disc designs. An unbalanced disc is solid, and results in a large pressure difference across the disc. This means that a large force is required for valve closure and opening. Balanced designs use pressure equalizing ports to balance the pressure above and below the disc. This makes the valve easier to operate, and reduces the torque required to open and close the valve. This is particularly advantageous for larger valves and high pressure applications.

More on globe valve flow characteristics

The manner in which fluids flow through a globe valve is a vital consideration, especially because these valves are used for precise flow control across their operating range. Important flow characteristics to consider are the valve's flow coefficient (Cv), and the valve's flow curve.

Valve flow coefficient (Cv)

A globe valve's flow coefficient (Cv value) represents the valve's flow capacity, and indicates the volume of fluid that can pass through the valve for a specified pressure drop across the valve. The valve flow coefficient is a function of the valve's design and internal geometry.

Flow curves

Globe valve flow curves represent the relationship between valve opening percentage (or valve lift) and the flow rate. The most common relationships are linear, quick opening and equal percentage.

Linear: The flow changes at a constant rate per unit of valve stroke, that is valve opening and flow rate are directly proportional.

Equal percentage: The percentage change in flow is equal to the percentage change in valve opening. In other words, there is an exponential relationship between valve opening and flow rate.

Quick opening: Provides a large increase in flow for a small initial opening.

Proper control valve selection and sizing is crucial to match the valve's flow characteristics with the application's requirements, ensuring efficient operation. The choice between linear, equal percentage and quick opening valves depends on the system's pressure dynamics and control needs.

Globe valve trims are available with a range of flow characteristics. This allows globe valves to be linear, equal percentage, or quick opening. Specialized trims are also available to mitigate cavitation and noise.

Advantages of Globe Valves

Excellent throttling: Precise, incremental control of flow is possible.

Reliability: Globe valves have proven to be reliable across a range of applications and operating conditions, providing good control and shut off capabilities.

Easy to maintain: For globe valves with bolted bonnets, the valve seat and disc are easily accessible, simplifying repairs.

Disadvantages of Globe Valves

High pressure drop: Unlike gate valves or ball valves, the indirect flow path through a globe valve results in a significant pressure drop across the valve.

High actuating force: A relatively large force is required to operate globe valves, especially in high-pressure applications.

Bulky and heavy: Globe valves are generally large and bulky, especially when compared to compact valves such as butterfly valves.

Slower operation: The multi-turn operation of globe valves is not suitable for applications that require fast opening or closing operation.

Globe Valve Applications

Globe valves are available in a variety of sizes, temperature and pressure ratings, material configurations and end connections, to suit an array of applications across a range of industries.

Common applications of globe valves include cooling water systems, bulk water and water treatment, plumbing and HVAC systems, boiler systems and oil and gas facilities. Examples include:

Steam Systems: Widely used in industrial facilities and power plants for controlling the flow of steam, due to their ability to handle high temperatures and high pressures.

HVAC Systems: Controls the flow of fluids, include water, steam, refrigerant and condensate, in heating, cooling, and ventilation applications.

Fuel Oil Systems: Used in fuel lines to control the flow of fuel to engines.

Water Supply and Treatment: Ideal for chemical dosing, filtration, pump station control and water distribution networks.

Globe Valves Optional Extras and Features

Globe valves may be specified with a range of optional features and accessories. These include bellow seals for zero stem leakage, low emission packing for environmental compliance, stem extensions for remote operation, locking devices for safety, actuator options, sanitary designs, a broad range of port configurations and end connections, and many materials of construction like brass, bronze, carbon steel and stainless steel to choose from.

Add image (actuated globe valve or extended stem)

Are Globe Valves the Right Control Valve for You?

Globe valves are the right valve for you, if your system needs accurate flow control over a broad flow range, while subjected to a high pressure drop across the valve. However if you are looking for minimal flow control capability in a valve, or if you are looking for a valve for isolation or shut-off functionality, then another valve like a ball valve, butterfly valve or gate valve might be the best option.

Our Posts

View AllGlobe Valve vs Ball Valve Comparison Guide | ValveMan

Valves are widely used in industrial and manufacturing facilities, but they’re also used in utilitie …

Read MoreNEMA Ratings Explained | ValveMan

Have you ever wondered what that little NEMA number on your electric actuator meant? Or perhaps, you …

Read MoreGate Valve vs Ball Valve Comparison Guide | ValveMan

Valves are widely used in industrial and manufacturing facilities, but they’re also used in utilitie …

Read MoreValve Inspection - Main Points of Valve Inspection and Testing in Manufacturing Settings

Industrial facilities rely on different types of valves (such as gate valves, check valves and ball …

Read MoreCan Ball Valves Be Used For Flow Control?

Ball valves are widely used in plumbing and piping systems, in fact, they are one of the most common …

Read MoreIntroducing Bonomi Valves

The Bonomi Group is a leader in industrial sectors including oil and gas, hydraulics, heating and en …

Read MoreUnderstanding Valve Actuators: Manual, Electric, Pneumatic and Hydraulic

Are you a beginner new to the valve world, ready to learn more about the various types of valve actu …

Read More3 Check Valve Mistakes to Avoid

So, you’re looking for a check valve, but you’re not sure if there’s any pitfalls to look out for? O …

Read MoreTypes of Valves in Plumbing

Have you ever wondered what goes into managing the flow of water in your home, or through a building …

Read MoreIntroducing Apollo Valves

Apollo Valves® inventory includes a wide range of valve products supplied to diverse markets. These …

Read MoreTypes of Water Valves

We all know that valves play a crucial role in regulating the flow of liquids and gasses in a broad …

Read MoreUnderstanding Valve Sizes and Measurement

Sizing the appropriate valve is critical to ensuring the performance of your system. Whether you'r …

Read MoreBall Valve Types and Applications

Ball valves are important components in a vast range of systems, from small family-owned workshops t …

Read MoreWhat is a Backflow Preventer, and How Does it Work?

When a simple check valve is inadequate for the job, you need a backflow preventer. But knowing you …

Read MoreUnderstanding valve standards and specifications

Hey there, fellow valve enthusiasts! Today, we're looking at valve codes, standards and specifica …

Read MoreHow to Tell if a Valve is On or Off

We’ve all been there —staring at a valve, almost certain you know whether it’s open or closed, but …

Read MoreUnderstanding Different Types of Valve Connections and Fittings

Hey there, fellow valve enthusiasts! We know valves play a crucial role in regulating the flow of li …

Read MoreTypes of Valve Handles: Lever and Handwheels

Whether you're involved in industrial work, plumbing, or you're a DIY enthusiast, you come across …

Read MoreThe Basic Parts of a Valve

Valves quietly work in many different areas, even places you wouldn't expect. They're truly everywh …

Read MoreGas Ball Valves In Industrial Applications - 5 Things to Keep in Mind

Unlike the standard ball valves, most gas ball valves are tested and approved by CSA. These valves a …

Read More