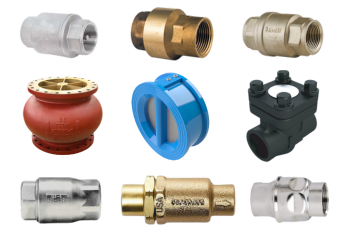

In-Line

Inline Check Valves

Shop Inline Check Valves Shop Now

Dual Disc

Dual Disc Check Valves

Shop Dual Disc Check Valves Shop Now

Wafer

Wafer Check Valves

Shop Wafer Check Valves Shop Now

Piston

Piston Check Valves

Shop Piston Check Valves Shop Now

Swing Check

Swing Check Valves

Shop Swing Check Valves Shop Now

Y-Check

Y Check Valves

Shop Y Check Valves Shop Now

Spring Check Valve

Spring Check Valve

Shop Spring Check Valve Shop Now

Vacuum Breaker

Vacuum Breakers

Shop Vacuum Breakers Shop Now

Ball Check Valves

Ball Check Valves

Shop Ball Check Valves Shop Now

Foot Valve

Foot Valves

Shop Foot Valves Shop NowWhat Is a Check Valve?

A check valve is a type of valve used in piping systems to control flow direction and prevent costly reverse flow. Designed with internal components such as a disc, flap, or ball, the valve opens when system pressure reaches a set threshold—known as the cracking pressure—and closes automatically if the flow tries to reverse. By allowing media to move freely in only one direction, check valves protect pumps, equipment, and entire systems from damage, leaks, or contamination.

Check valves operate on a simple but essential principle: they allow media to move in one flow direction while automatically closing if the flow tries to reverse. This one-way action prevents costly system failures caused by reverse flow, such as pump damage, leaks, or contamination.

Inside the valve, a disc or other mechanism opens once the system pressure reaches a specific threshold known as the cracking pressure. Below this point, the valve remains closed. Once the pressure exceeds the cracking pressure, the disc lifts and fluid passes through in the intended flow direction. If pressure drops or flow attempts to reverse, the valve shuts again, ensuring the system stays protected without manual operation.

This automatic action makes check valves a reliable safeguard in piping systems where maintaining steady, one-way flow is critical.

What Are the Common Applications of Check Valves?

The check valve is a versatile and useful item, which has led to it being used in a wide range of applications. Let’s take a closer look at some of the most common uses for these valves:

- Plumbing Systems: Check valves are commonly used in plumbing systems to prevent the backflow of water or sewage. They ensure that water flows in one direction, preventing contamination of the potable water supply or sewage backup.

- Irrigation Systems: Check valves are a regularly used addition to irrigation systems to ensure that water flows in the desired direction and to prevent water hammer caused by sudden valve closure. They help maintain system efficiency and prevent water wastage.

- Pharmaceutical and Food Processing: Check valves are crucial in pharmaceutical and food processing industries to prevent the backflow of contaminants, ensuring the purity and safety of the products being processed. They are often used around equipment such as pumps, filters, and separators.

- Chemical Processing: Check valves find extensive use in chemical processing plants to control the flow of various chemicals and prevent the mixing of incompatible substances. They help maintain the integrity of the system, prevent contamination, and ensure the safety of personnel and equipment.

Types of Check Valves

There are many different types of check valves with slightly different uses and applications. Some of the most common types include the following:

Swing Check Valves

Swing check valves are likely one of the most basic types (mechanically). It contains a simple hinged flap or disc that can only open in one direction. This effectively blocks flow in the opposite direction.

Ball Check Valves

Ball check valves use a ball, or ball-shaped disc, that can freely move around in the valve. When fluids move in the valve’s “open” direction, it recedes to allow flow. If fluids attempt to flow in the opposite direction, the ball blocks the flow.

Double Check Valves

Double check valves contain two checks to provide extra security against backflow.

Spring Check Valves

Also known as lift check valves, these valves contain a spring-loaded disc that springs into place whenever liquids try to flow in the wrong direction. They’re typically required on vertical applications to counteract gravitational pull.

Advantages of Using Check Valves

There are many discernible advantages that result from using check valves. Some of the most significant advantages include the following:

- Preventing Backflow: The primary function of check valves is to prevent backflow or reverse flow of fluids. They ensure that fluids flow in one direction only, preventing contamination, damage, or interference with equipment and systems. They’re commonly used in vertical installations to help combat gravitational pull.

- Simplified System Design: Check valves simplify system design by eliminating the need for additional components or complex piping arrangements to prevent backflow. They provide a simple and effective solution for flow control in pipelines and systems.

- Low Maintenance: Check valves typically have a simple design and require minimal maintenance. They are usually self-operating, relying on fluid pressure to open and close. This characteristic reduces the need for frequent inspection or manual intervention.

Why Choose ValveMan.com

With over fifty years experience in the check valve industry, ValveMan.com promises that you will get the best technical advice as to which one way check valve best suits your specific needs, regardless of the complexity of the project. ValveMan is a valve store dedicated solely to selling valves. It’s simply what they do and what they do best. Discover ValveMan.com today.

Frequently Asked Questions (FAQs)

What are the pressures that these valves can handle under different operating conditions?

Check valves are made in a variety of different pressure ratings based on their body design and position. For example, in industry there are large valves that can be installed in high pressure line of steam or chemicals and smaller check valves designed for low pressure water service. Always select a valve rated for your system operating conditions to maintain the integrity of your system.

What are the recommended valve materials for water service, steam service, and chemical service?

Selecting the appropriate valve material for your application is extremely important for longevity. For instance, in a corrosive or high temperature situation, stainless steel is needed; for food or irrigation applications brass or PVC may be good low-cost options; and for chemical processing there may be special alloys or lined body materials that are important to ensure damage caused by corrosion is avoided.

Can check valves be used with gases (including air and/or fuel gases)?

Yes! Check valves are used on pipelines conveying gases, including air or natural gas or other fuel gases. In these situations the important issue is select the proper sealing device and body materials that can handle the system pressures and avoid leaks, and operating the inlet/ outlet connections correctly to ensure safe operation of the piping system.

Are these suitable for oil service and what design factors affect how well they perform in oil?

Some industrial check valves are designed to be suitable for oil service. They must be closing such that backflow does not occur and the materials of the body and seals must be suitable to avoid breakdown from petroleum products. When selecting the correct seal and pressure differential rating of the valve, it will assist in protecting efficiency and avoiding damage.

When should I choose a valve with stainless steel opposed to carbon steel?

A stainless steel check valve is probably going to be your "default" choice when it comes to corrosion resistant, for example, a chemical plant or marine environment; or you may consider carbon steel or cast iron body options for general water and medium oil service. You will have to consider the application and line conditions.

How is a check valve installed in a vertical line, opposed to a horizontal line?

In regards to installation orientation, it does matter; in a vertical line, you will want a spring-loaded or lift check valve that will close properly due to gravity. In horizontal lines you can use a swing or dual disc check valve. Remember to always follow the arrow on the body of the valve, as it identifies flow direction when installing.

What do valve body types impact (temperature, corrosion, and durability)?

The valve body will determine, how durable the check valve is in terms of heat, pressure, and harmful effects of corrosion. A stainless steel valve body is practically chemically resistant, while traditionally brass and bronze have served their purpose for plumbing and irrigation. Choosing the right body materials reduces incidences that can jeopardize system integrity, while also prolonging the life of the valve.

What determines closing time, and the reliable closure of the check valve?

The mechanism type and internal parts, plus the system flow rate, pressure differential to the return line, determines how fast and reliable the check valve closes. When a check valves are properly sized, it can prevent the hard slam shut, basically eliminating the risk of a full water hammer downstream. If installed properly, check valves will be dependable, even if their sealing mechanism is inspected frequently.

How is a check valve sealed, and what types of seals are there for different media?

Check valves seal tight through a disc, ball, or plate that is firmly pressed onto a seat inside of the body. You can specify elastomer and Teflon seals for aggressive chemicals or gases. Check valves used in high-pressure industrial service typically use metallic to metallic sealing to limit wear and/or failure in the system.

What is the risk downstream of a check valve with a fast closure? Can it cause water hammer?

If a valve closes quickly, and the flow reverses, downstream pressure can be created by a pressure wave and cause water hammer. Water hammer can damage piping or pumps. The right valve size, the right materials, and the right style of valve can help alleviate pressure drop and consequently line shock.

What is the difference between an industrial check valve as opposed to a residential check valve?

Industrial check valves are purpose built and factory tested to handle way more than residential service (high flow rate, oils or gases, corrosive fluids) The construction material of industrial valves can sometimes withstand more abusive operating conditions, provide better sealing mechanisms, as well as withstand much greater allowable pressure differentials than valves made for a residential plumbing system.

Is a ball check valve the best option when I want the lowest amount of pressure drop?

From what I understand, ball check valves are normally thought of to be the lowest amount of pressure drop design available. Ball check valves can sometimes represent the best selection of check valve when maintaining flow and efficiency is of utmost priority. The spherical disc operates freely to permit forward flow and will latch tightly shut when the pressure reverses.

How can I stop backflow in a pump's discharge line?

Installing a properly sized check valve on the inlet or discharge line of a pump will help prevent backflow and maintain your system's integrity. For vertical applications a spring loaded valve is helpful to ensure you're closing properly in any orientation.

Where will I find the flow direction arrow on the body of the valve and how do I reference it when I install the valve?

There is always a cast or stamped arrow on the body of a check valve that indicates the direction of flow. If it is installed improperly, it will not close properly and may allow backflow. Always align the arrow in the forward flow line.

What are general inlet and outlet connection types.

Inlet and outlet connections are dependent on valve size and materials. Common options are threaded ends for plumbing, flanged ends for industrial check valves, and socket welds for high pressure lines. You will need to ensure that the connection you use matches your joining method and piping system.

How does corrosion affect the service life and what valve materials are more resistant to corrosion.

Corrosion destroys or weakens the body and eventually overrides the effectiveness of the seal. Stainless steel and bronze are the most common materials that are resistant to corrosion, particularly in chemical or marine service. A routine inspection will verify if the valve can perform when put to pressure.

What is the difference between open position and closed position on a swing check.

The swing check is open when the disc rests in a vertical or slightly angled position allowing unlimited flow rate through the line. The swing check is in the closed position when the disc returns against the seat and seals the body's flow line allowing the valve to prevent backflow. Swing transition is part of the normal closing process.

How much pressure drop should I expect across a check valve at any given flow rate?

Pressure drop is created by all check valves - the amount of pressure drop will be dependent upon flow rate as well as the valve body design and materials. For check valves with low pressure drop, a ball check valve is one recommendation which can minimize energy loss, short period of spirit service and maintain system efficiency.

How do I size for flow rate to avoid excessive line losses?

The proper sizing of a check valve will allow the flow rate to stay within reasonable limits, minimizing pressure drop, and training system integrity. If the valve is oversized it won't even reach its cracking pressure, and if the valve is undersized it will impede forward flow rate and finish prematurely.

What regular checks indicate it’s time to replace seals or the whole body of the valve if required?

Any visible corrosion on the body, worn seals leaking, improper closing characteristics and abnormal fluctuating pressure rates downstream. In either case of replacement of the seal or whole valve, it is in the best interest of the piping system to maintain integrity and reduce failures related to backflow.

Check Valves - Related Articles

How Do Check Valves Affect Water Pressure in the Piping System?

What is the cracking pressure of a check valve?

What Check Valve Should I Use for my Application?

The Perfect Check Valve for Water Processing

888-825-8800

888-825-8800