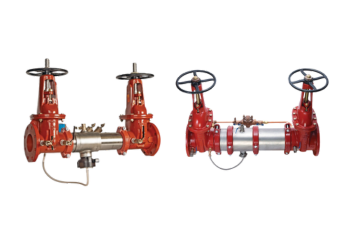

Reduced Pressure Detector Assemblies

Reduced Pressure Detector Assemblies

Shop Reduced Pressure Detector Assemblies Shop Now

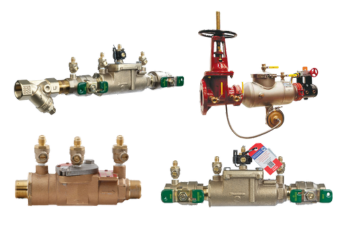

Double Check Valve Assemblies

Double Check Valve Assemblies

Shop Double Check Valve Assemblies Shop Now

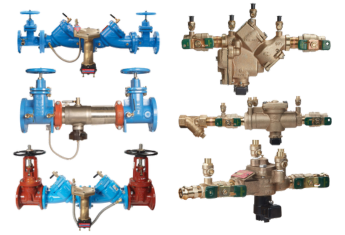

Reduced Pressure Zone Assemblies

Reduced Pressure Zone Assemblies

Shop Reduced Pressure Zone Assemblies Shop Now

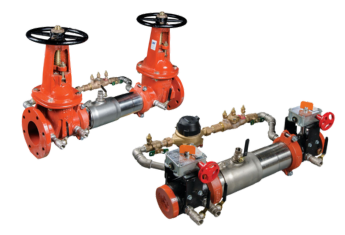

Double Check Detector Assemblies

Double Check Detector Assemblies

Shop Double Check Detector Assemblies Shop Now

Dual Checks/Dual Checks with Atmospheric Vent

Dual Check Valve Backflow Preventers

Shop Dual Check Valve Backflow Preventers Shop Now

Backflow Preventors Accessories

Backflow Preventer Accessories

Shop Backflow Preventer Accessories Shop NowWhat are the Benefits of Using a Backflow Preventer?

A backflow preventer is an essential component in pipelines involving cross-connections. While a check valve is commonly associated with preventing backflow, an actual backflow preventer performs a more specific duty and is a bit more complicated in design.

Principally, both prevent fluid from traveling backwards in a line, but a check valve in itself is not an absolute, particularly in functions that demand backflow prevention, such as piping systems utilizing added chemicals, or are prone to frequent pressure loss, or absolutely must not fail.

These pipeline assemblies typically involve potable water, where contamination from sewage, chemicals, etc. can spell disaster. Major applications will include plumbing and other waterworks, irrigation systems, and fire prevention systems. Check how backflow valves can improve your plumbing services and help your clients avoid contamination!

What Are the Differences Between Backflow Preventers and Check Valves?

A check valve is fairly simple. It allows fluid to flow in one direction, and stops it from traveling back through the valve if the fluid reverses direction. A ball, or clapper, automatically moves to stop the flow when the pressure drops below cracking pressure (the amount of fluid pressure required to open the valve). This is a very reliable system for countless applications, but it can fail if something becomes lodged between the ball and the seal, and therefore, it is not suitable for multi-purpose pipelines, which include supplying fresh drinking water.

A backflow preventer, on the other hand, incorporates 2 (sometimes more) check valves, which are controlled by a pressure-sensing diaphragm, and a dead space where the fluid is trapped until pressure is equalized on both sides. This is a fail-safe measure designed specifically to divert fluid--through a relief valve--from traveling in either direction should a seal falter.

The Types of Backflow Preventers

There are two main kinds of backflow preventers you can install to protect your clients from harmful damage, divided into several subtypes. They are as follows:

Backflow Prevention Device

Backflow prevention devices allow you to prevent the reversal of flow in plumbing systems. However, you can't test them post-installation because they don't have an inlet valve shutoff, outlet valve shutoff and test valves.

Atmospheric Vacuum Breaker

An atmospheric vacuum breaker (AVB), also referred to as an atmospheric antisiphon, is a commonly used backflow device. They come in various forms, including frostproof wall hydrant faucets and household hose bib vacuum breakers.

In the case of this device, water pressure is not the most important for its functioning - it relies mostly on air pressure. It has an air inlet valve that stays closed when water flows in the right direction. If the water flow reverses, the air inlet valve opens so as not to allow for back-siphonage.

Backflow Prevention Assembly

A backflow assembly has all the requisite valves and shutoffs for testing, and it is recommended to test it on a regular basis to make sure it functions properly. Some of the most popular backflow prevention assemblies are:

Pressure Vacuum Breaker

Pressure vacuum breakers (PVB) work in a similar way to AVB but with a significant difference - they have spring-loaded check valves, an outlet shutoff valve and test valves. As a result, they can be used for high-hazard purposes or where valves are downstream.

If you install a PVB outside, you need to protect it from freezing. To make it possible for you to make sure they work correctly, they are equipped with test cocks with specially-calibrated gauges.

Double-Check Valve

Another common choice for backflow prevention is a double-check valve assembly (DCVA). It can be installed in both indoor and outdoor plumbing systems, either horizontally or vertically, and it is most often used for in-line or underground applications.

In double-check valves, you can find four test valves, two spring-loaded and independently working check valves, as well as an outlet shutoff valve. Importantly, in order to be able to maintain the DCVA properly, you need to provide at least a foot of clearance.

Spill-Resistant Vacuum Breaker

To provide additional protection against water leakage, maintenance superintendants often invest in more advanced backflow valves, such as spill-resistant vacuum breakers (SVBs). They have a similar structure to PVBs, but they are additionally equipped with diaphragm seals to prevent water from spilling out of the air inlet when there's higher pressure inside.

Reduced Pressure Principle Backflow Assembly

One of the safest and most reliable backflow preventers on the market is a reduced pressure principle (RP) backflow assembly. It usually has an inlet shutoff valve, an outlet shutoff valve, four test valves, and a pressure differential release valve separating two independent spring-loaded check valves.

Such a backflow assembly is suitable for various configurations. Normally, underground installation suggests straight, in-line installation, but in the case of above-ground installation, you can do it in a more compact form to save space. In most cases, it needs to be installed horizontally, but there are assemblies with an option to be set for vertical installation.

Are Backflow Preventers Useful for Your Clients?

A backflow preventer is advantageous if a foreign object lodges itself in the clapper (check valve), causing it to stick open. Here, the ordinary check valve will fail, allowing fluid to travel either direction through the valve, while a backflow preventer will trap and divert the fluid rather than allowing it to pass.

Because of the pressure-sensing diaphragm, this same scenario is repeated should something be lodged in the second check (the other check valve). Back siphonage is prevented in much the same way--fluid traveling in the wrong direction will not activate the diaphragm; the check valve remains closed.

Often, intricate and problematic piping systems involving cross-connections are code-required to utilize a fail-safe for eliminating back siphonage, which can result in contamination. This phenomenon can occur at these critical cross-connections--common in potable water pipelines servicing large office buildings or apartment complexes-- because they are tied into sewage disposal lines.

When a break in service occurs or during a fire hydrant flush (for simple examples), it causes significant pressure loss. Without backflow prevention, line pressure changes can lead to contaminated water back siphoning into drinking water feed lines.

Also known as an RP (reduced pressure) or an RPZ (Reduced Pressure Zone) valve, a backflow prevention device is furthermore beneficial to irrigation systems, which are prone to problems--pressure drops--similar to drinking water systems. This can happen during a pressure loss, allowing chemicals to siphon back into the fresh water supply.

Pesticides and fertilizers must not be allowed to contaminate watering systems, where they could be potentially harmful. Installed at cross-connections, a backflow preventer keeps the chemicals from the potable water supply.

Likewise, fire systems rely on stored water that can become contaminated with bacteria. Preventing backflow and back-siphonage is therefore crucial for obvious safety reasons when the system is connected to a potable water line.

Addressing these issues is beyond the limits of a simple check valve, and necessitates the utilization of a backflow preventer. The Apollo Valve 4ALF-100 and 200 Series offer top-of-the-line technology in backflow and back-siphonage protection.

The Benefits of Having a Backflow Preventer Installed

Either an industrial or residential backflow preventer can provide your clients with numerous benefits. Here are some of the most important ones you can mention to them:

- Securing a public water supply to protect public health

- Minimizing the risk of pipe damage

- Enhancing water system efficiency

- Keeping water quality at the same level

- Protecting properties

- Ensuring compliance with legal requirements

Who Makes Some of the Best Backflow Preventers?

One of the most appreciated backflow regulator manufacturers is Apollo. Check out some of the products we recommend to improve your plumbing services!

Apollo 4ALF-100 and 200 Series

For potable water and plumbing applications that require meeting the Clean Water Act's restrictions and for use in other piping systems where backflow and back-siphonage must be eliminated, the 100 double check valve assembly and the top entry reduced pressure zone assembly 200 series are essential, as both are lead-free, and both are manufactured in the United States. (Replaces the original 4A Series, but parts are interchangeable).

Apollo 4ALF-100 Series - Key Features:

- Constructed of lead-free (LF) bronze - these double-check valve assemblies feature FNPT connections, modular cartridge checks, reversible silicone seat discs, ball valve shut-offs, and replaceable check seats.

- Available in 2".

- Check covers are threaded into the housing.

- Check assemblies modules--constructed of industrial grade plastic--are self-contained.

- Dual shut-offs.

- Can be mounted vertically (up) or horizontally.

Apollo 4ALF-200 Series - Key Features:

- Lead-free (LF) bronze construction, top entry, reduced pressure assembly features modular cartridge checks, reversible silicone seat discs (1/2" to 2"), and replaceable seats.

- Ball valve shutoffs with stainless steel (SS) handles and trim.

- Test cocks are top-mounted.

- Elastomers are chloramine-resistant.

- Maximum working pressure to 175psi.

- Temperatures between 33 degrees F and 180 degrees F.

Key Features of Both Apollo Backflow Valves:

- Both the 100 and 200 Series are approved by the Foundation of Cross Connection Control and Hydraulic Research, University of Southern California, and are ASSE (1015), IAPMO, and CSA (B.64.5) approved.

- Both operate in temperatures ranging between 33 and 180 degrees F, and 175psi.

- Low-pressure loss.

- Compact, easy maintenance requirements.

- No specialized tools are required.

- Repair kits are available.

- 5-year domestic warranty for either series.

- Compliant with potable water systems.

Where to Buy an Apollo Backflow Prevention Valve at a Low Price?

Backflow prevention is a crucial element in many piping systems, regardless of the fluids or materials they may be transporting. And, keeping up with today's potable water lead restrictions is another concern for piping systems that require a water backflow preventer. When you are buying these specialty valves, consider Apollo's 4ALF series first, and consider buying them from an industrial-grade valve supplier who has been in the business for over 50 years.

The ValveMan.com valve store is proud to offer Apollo lead-free backflow preventers, as well as an extensive list of other great Apollo valves. In fact, all we sell are valves. It's what we do, and we do it better than anyone else. Check out our offer and contact us if you have any questions!

FAQ on Backflow Preventers

- What issues can be caused at your client's property by a damaged backflow water valve?

If a backflow regulator doesn't work well, it can lead to a mess in your client's bathroom or kitchen because of the drain buildup. What’s more, in the case of industrial uses, damaged backflow valves can lead to water supply contamination and major fines. For this reason, it should always be well-maintained and quickly replaced whenever necessary. - Why should a supplier use a backflow valve for a water line?

Backflow can cause pollution or contamination in a public water system, and each supplier needs to do everything they can to keep their drinking water safe to avoid serious consequences. - Do backflow valves need a lot of maintenance?

A backflow preventer valve is considered "non-testable," and it only needs to be rebuilt or replaced once every five years.

Backflow Preventers - Related Articles

Deciphering Backflow Preventers

888-825-8800

888-825-8800