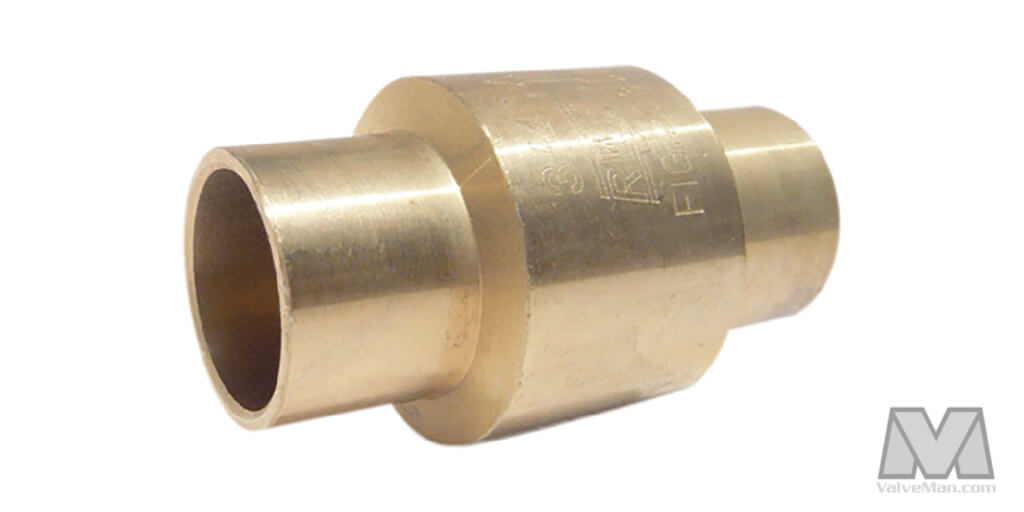

In-Line

Inline Check Valves

Shop Inline Check Valves Shop Now

Dual Disc

Dual Disc Check Valves

Shop Dual Disc Check Valves Shop Now

Wafer

Wafer Check Valves

Shop Wafer Check Valves Shop Now

Piston

Piston Check Valves

Shop Piston Check Valves Shop Now

Swing Check

Swing Check Valves

Shop Swing Check Valves Shop Now

Y-Check

Y Check Valves

Shop Y Check Valves Shop Now

Spring Check Valve

Spring Check Valve

Shop Spring Check Valve Shop Now

Vacuum Breaker

Vacuum Breakers

Shop Vacuum Breakers Shop Now

Ball Check Valves

Ball Check Valves

Shop Ball Check Valves Shop Now

Foot Valve

Foot Valves

Shop Foot Valves Shop NowCheck valves are a highly useful piece of plumbing equipment that serves a fantastic purpose in terms of protecting systems from contamination. They also play a vital role in preventing leaks during periods when systems are not in use. When placed on the discharge side of a pump, these valves also help prevent the pump from “dry running”. Let’s take a closer look at some different types of check valves and what they’re used for.

What Is a Check Valve?

A check valve is a unique type of fitting that prevents liquids and gases from flowing in the wrong direction. Check valves are calibrated to allow flow in a single direction and have a flap, disc, or ball, which closes the passage when a fluid wishes to flow in the opposite direction.

What Are the Common Applications of Check Valves?

The check valve is a versatile and useful item, which has led to it being used in a wide range of applications. Let’s take a closer look at some of the most common uses for these valves:

- Plumbing Systems: Check valves are commonly used in plumbing systems to prevent the backflow of water or sewage. They ensure that water flows in one direction, preventing contamination of the potable water supply or sewage backup.

- Irrigation Systems: Check valves are a regularly used addition to irrigation systems to ensure that water flows in the desired direction and to prevent water hammer caused by sudden valve closure. They help maintain system efficiency and prevent water wastage.

- Pharmaceutical and Food Processing: Check valves are crucial in pharmaceutical and food processing industries to prevent the backflow of contaminants, ensuring the purity and safety of the products being processed. They are often used around equipment such as pumps, filters, and separators.

- Chemical Processing: Check valves find extensive use in chemical processing plants to control the flow of various chemicals and prevent the mixing of incompatible substances. They help maintain the integrity of the system, prevent contamination, and ensure the safety of personnel and equipment.

Types of Check Valves

There are many different types of check valves with slightly different uses and applications. Some of the most common types include the following:

- Swing Check Valves - Swing check valves are likely one of the most basic types (mechanically). It contains a simple hinged flap or disc that can only open in one direction. This effectively blocks flow in the opposite direction.

- Ball Check Valves - these valves use a ball, or ball-shaped disc, that can freely move around in the valve. When fluids move in the valve’s “open” direction, it recedes to allow flow. If fluids attempt to flow in the opposite direction, the ball blocks the flow.

- Double Check Valves - Double check valves contain two checks to provide extra security against backflow.

- Spring Check Valve - Also known as lift check valves, these valves contain a spring-loaded disc that springs into place whenever liquids try to flow in the wrong direction. They’re typically required on vertical applications to counteract gravitational pull.

Advantages of Using Check Valves

There are many discernible advantages that result from using check valves. Some of the most significant advantages include the following:

- Preventing Backflow: The primary function of check valves is to prevent backflow or reverse flow of fluids. They ensure that fluids flow in one direction only, preventing contamination, damage, or interference with equipment and systems. They’re commonly used in vertical installations to help combat gravitational pull.

- Simplified System Design: Check valves simplify system design by eliminating the need for additional components or complex piping arrangements to prevent backflow. They provide a simple and effective solution for flow control in pipelines and systems.

- Low Maintenance: Check valves typically have a simple design and require minimal maintenance. They are usually self-operating, relying on fluid pressure to open and close. This characteristic reduces the need for frequent inspection or manual intervention.

Why Choose ValveMan.com

With over fifty years experience in the check valve industry, ValveMan.com promises that you will get the best technical advice as to which one way check valve best suits your specific needs, regardless of the complexity of the project. ValveMan is a valve store dedicated solely to selling valves. It’s simply what they do and what they do best. Discover ValveMan.com today.

Frequently Asked Questions (FAQs)

How Do I Select the Right Check Valve for My Application?

Choosing the right check valve for your application is simple. Merely ensure that your valve is the right size and consists of a material that won’t react with the fluids you’re transporting.

One additional factor that many people fail to consider is that the addition of a check valve affects the lift and delta pressure within a system. If you don’t know how to accommodate that, please contact an expert.

Finally, you need to consider whether you require the valve to close without making noise. In that case, consider a silent check valve.

Can Check Valves Be Automated?

Check valves cannot be automated, as they are self-operating. These components operate without any intervention and don’t require an actuator or another form of automation.

How Should Check Valves Be Maintained?

Check valves generally require minimal maintenance. However, when using a check valve as part of any system, you’d be wise to ensure that it receives regular cleaning and gets tested regularly.

Where Can I Buy Check Valves?

Right here at ValveMan! We have an array of different check valves for sale at the best prices. Feel free to check out our check valve collection!

Check Valves - Related Articles

How Do Check Valves Affect Water Pressure in the Piping System?

What is the cracking pressure of a check valve?

What Check Valve Should I Use for my Application?

The Perfect Check Valve for Water Processing