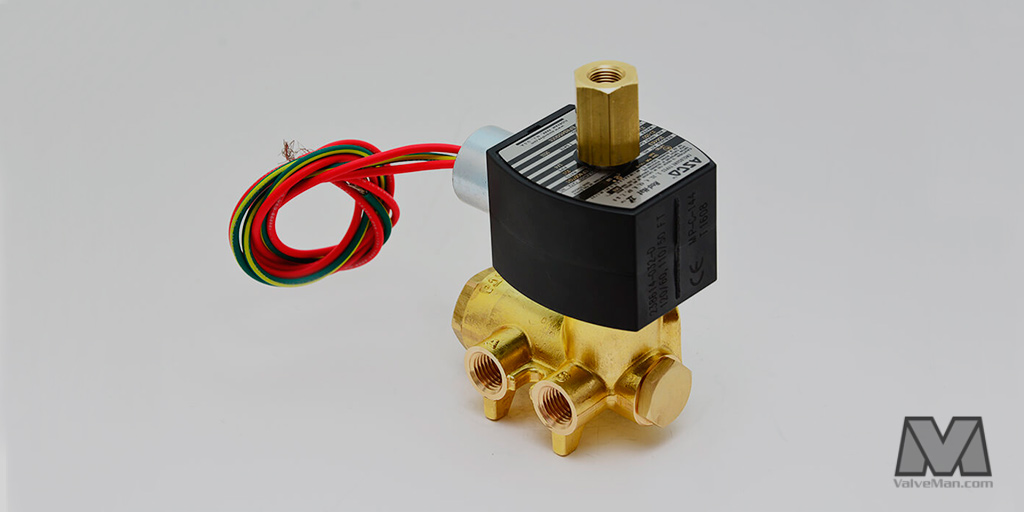

In the world of fluid controls, 4 way valves are the workhorses that ensure optimal functioning and control. Popular across many industries, they play a key role in managing the flow of liquids, gases, or steam within various systems. Standing out amongst other valve types due to their ease of use, durability, and versatility, 4 way valves are essentially devices that incorporate four ports into their design, two more than the common 2 way valves. These include two inlet ports, one being the pressure or supply port and the other serving as the exhaust port, and two outlet ports which connect to the actuator.

Simply put, a 4 way valve consists of a casing containing an internal mobile component (either a ball or a disk), which rotates or slides to adjust the formation of the internal passages and subsequently control the flow through the valve. These valves can support various configurations allowing you to either divert flow between different sources or mix various fluids.

From brass, through bronze, all the way to PVC valves, you can be sure to find the 4 way valve you’re looking for easily at ValveMan.

How Do 4 Way Valves Work?

The functionality of a 4 way valve revolves around its design. Generally, these valves are operated manually, pneumatically or electrically using an actuator. Electrically actuated valves are preferred when precision in control is essential.

The operation involves shifting the valve's internal component to align with specific ports opening or closing them as required. For instance, in a typical setup with an actuator, when the actuator is in a neutral position, the valve blocks flow from the pressure port to both cylinder ports while allowing flow between each cylinder port and exhaust. As the actuator moves either forward or backward, this opens the corresponding path from pressure port to one cylinder port and from the other cylinder port to exhaust.

This structural shifting accommodates both simple shutoff functions as well as complex control scenarios facilitating precise regulation of fluid direction and flow velocity.

Where Are 4 Way Valves Used?

Given their versatility, 4 way valves have a broad range of applications across a multitude of industries. They are commonly utilized in industries such as hydraulics, HVAC systems, water utilities, chemical processing, agriculture irrigation systems, and more.

In hydraulic systems such as heavy-duty machinery or industrial plants, 4 way valves are invaluable for controlling the movement of hydraulic cylinders or pistons. In HVAC systems, they can regulate the flow of heating or cooling medium to allocate it as needed. In water utilities, these valves help ensure proper routing of water through complex piping systems. In the world of automation, they are essential in control and signal processing systems, serving as diverter valves.

How to Choose the Right 4 Way Valve?

Choosing the right 4 way valve involves consideration of multiple factors directly related to where you intend to use it and what you need it to do. Here are the key factors to consider:

- Material: The valve material should be resistant to the specific fluid it will handle. For example, stainless steel handles corrosive fluids well, while brass valves are suitable for non-corrosive fluid.

- Size: The size and type of ports in your system will dictate what valve size is required.

- Pressure and temperature: Valves come with specific pressure and temperature ratings, which must fall within your system's operational parameters.

- Flow Rate: Depending on the required flow rate in your system, you need to select a valve that can accommodate this while still providing efficient operation.

- Actuation Method: Consider if a manually operated valve will suffice or if you require an electric actuator for more precise control.

Once you determine the type of 4 way valve you need based on the factors listed above, you can head on and select the ones you need from the products shown on this page. No matter the material, size, or actuation method, ValveMan is your one-stop-shop for all your valve-related needs!

Maintenance and Lifespan of 4 Way Valves

Achieving the maximum functionality and longevity of your 4 way valves can be made possible through proper maintenance and a clear understanding of their lifespan. Regular inspection for wear and tear, and immediate replacement of faulty parts can significantly extend a valve's effective operation period. These replacement parts are readily available at ValveMan, your reliable online valve store.

It's crucial to know that the lifespan of these valves can also be influenced by the type of medium passing through them and the environment they operate in. Under normal operating conditions and with proper inspection practices, these valves can function efficiently for over a decade or more. Made using robust materials like brass or stainless steel, they are designed to withstand considerable pressure and temperature fluctuations.

Choose ValveMan for 4 Way Valves and All Your Other Valve Needs

At ValveMan, we offer an extensive selection of 4 way valves, equipped to meet the demands of various applications across multiple industries. We are proud to stand by our quality products and committed to helping you choose the perfect valve to match specification needs. Our team of experts is always ready to provide information and advice, ensuring you make the right choice for your application. Explore our range of 4 way valves today.

Of course, 4 way valves aren’t the only type of valves we have in stock at ValveMan. Whether you need something really simple to control the flow of water at your house, or a wide set of ball valves to be used in industrial settings, you can be sure to find it here.

Resources

Our Posts

View AllAgriculture Irrigation Valves: Efficient Flow Control for Farms

Agriculture irrigation valves are vital for efficient flow control, and valve selection is rarely ab …

Read MoreBackflow Prevention Devices

According to the American Backflow Prevention Association, 24 gallons of asphalt emulsifier, intende …

Read MoreTop 10 Swing Check Valves by Model & Manufacturer

Looking for reliable swing check valves? Discover the top 10 models from leading manufacturers like …

Read MoreWhat is a Spool Valve and How Does It Work?

Spool valves are incredibly useful. They are a simple directional control valve used in hydraulic an …

Read MoreWhat is the cracking pressure of a check valve?

Check valves, regardless of their individual design, serve the specific purpose of permitting the fl …

Read MoreSmart Water Valves: Futuristic Flow Control Technology

Leaks can range from annoying to devastating, and the longer they go unaddressed, the more costly th …

Read MoreHow to Calculate Flow Rate In Water Systems

Flow rate is critical in water systems, from simple home plumbing to complex industrial water system …

Read MoreWhat Is a Valve Pressure Rating? Definition and Guide

Pressure ratings are important considerations when designing a system that uses valves, but they can …

Read MoreSpecial Pricing and Services for OEM - the ValveMan Valve Store

OEMs or Original Equipment Manufacturers make up a large portion of our clients at ValveMan. With th …

Read MoreData Cooling Centers and Sanitary Valves

Overheated data centers pose a massive challenge, and the global data center cooling market is growi …

Read MoreValve Maintenance Best Practice Guide

A Guide to Safer, Long Lasting Valves Valves are found in most piped systems that move liquids, gas, …

Read MoreValve Materials for Gaseous Oxygen Service

Oxygen may seem safe because it is colorless, tasteless, and odorless, but in the wrong conditions, …

Read MorePneumatic Actuators Valve Types

Have you ever stopped to think about what makes an automated assembly line push, pull, lift, and rot …

Read More-320°F Liquid Nitrogen Cryogenic Control Valve Setup

Need a valve that can handle -320°F liquid nitrogen without freezing up — and still control flow? He …

Read MoreWhy Fall is the Perfect Time for Valve Maintenance (And What Happens If You Wait)

We're well into fall now, which means it's time for that conversation nobody wants to have: winter p …

Read MoreFrom the DMZ to Bonomi: Rick Wentzel’s Valve Legacy

In the inaugural episode of the Fully Open podcast, host Gil Welsford sits down with Rick Wentzel of …

Read More

Check Valve vs Backflow Preventer Comparison | ValveMan

If you need to make sure that fluid in your pipe system flows in one direction only, and prevent rev …

Read MoreDifferent Types of Gas Shut Off Valves | ValveMan

Whether you're upgrading your residential gas system, looking for the best gas shut off valve for yo …

Read MoreGlobe Valve vs Ball Valve Comparison Guide | ValveMan

Valves are widely used in industrial and manufacturing facilities, but they’re also used in utilitie …

Read MoreNEMA Ratings Explained | ValveMan

Have you ever wondered what that little NEMA number on your electric actuator meant? Or perhaps, you …

Read More

888-825-8800

888-825-8800