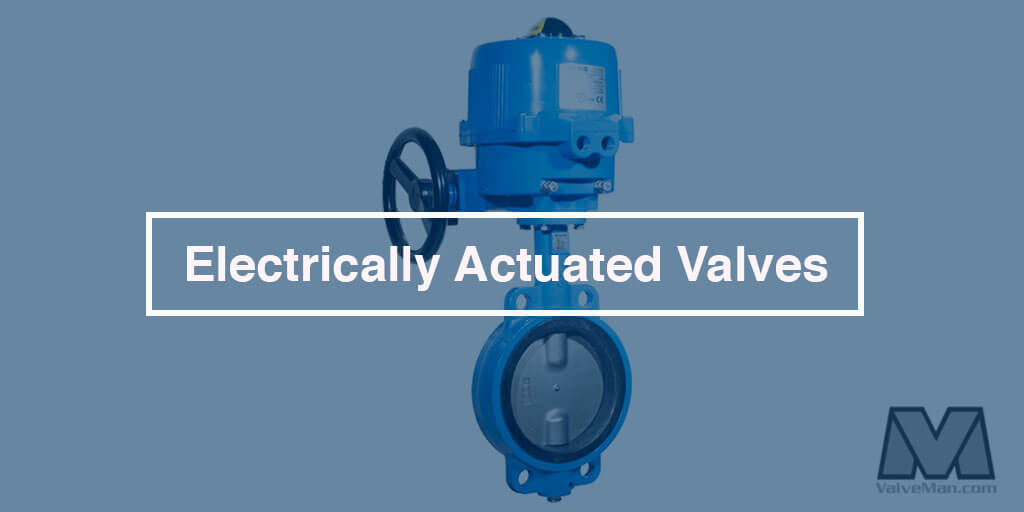

Electricity moves at the speed of light, making electrically actuated valves highly proficient in fast closing and opening actions. Electric actuators employ an electric motor which provides the valve needed torque for operations. Generally quiet and cost efficient, electrically actuated valves are a smart investment for countless applications.

Electrically Actuated Valve Types

There are different types of electrically actuated valves, though the most basic workhorse is the rotary design. Rotary actuators employ an electric motor and shaft mechanisms to create rotational movement to open and close a valve. Most rotary actuators are coupled with 1/4 turn valves, can be direct mounted, and are perfect for automation applications. Like all electrically actuated valves, they provide precise positioning and control. Another common type of electric actuator is known as a linear actuator. Rather than a rotational movement, linear actuators perform a push/pull movement, converting electric energy into straight line motions. Electric linear actuators are typically used in positioning applications. They are often powered and controlled by step motors and servos. Electrically actuated linear control valves are far less common than rotary styles, though, and tend to be expensive.

Why Use Electric Actuators?

While speed is only one factor when considering the right type of actuator for your application, the power source may be the most important. While it's not always readily available, electricity is the most common power source for any shop or plant, and is easily the most cost effective, making electrically actuated valves the natural choice. Depending on the number of actuated valves being supplied, it can be quite a draw on an electrical supply. However, compared to the cost of supplying power to a pneumatic system, it's much cheaper. An air compressor runs continuously, even when idling, constantly drawing power. Another big advantage of electric actuators becomes apparent when they are used for more than one task. Changeovers in a factory can be time consuming, and therefore expensive. Because electrically actuated valves are easily programmed or set for a specific function speed, they substantially reduce changeover costs.

Recommended Electrically Actuated Valves

These are just a few examples of electrically actuated valves available through the ValveMan.com valve store. We carry a variety of sizes, models, and configurations for almost any application. We've been in the industrial valve business for over 50 years. It's simply what we do, and we do it better than anyone else.

Electrically Actuated Valves - Related Articles

What is a Duty Cycle and How Does it Relate to Electric Ball Valves?

Practical Guide To Electric and Pneumatic Actuators – Which One To Choose?

Using an Actuated Ball Valve Or a Solenoid Valve For Best Fluid Control In The System

The Future of Electric Flow Actuation

Why Choose a Namur Solenoid Valve for a Pneumatic Actuator

Types of Valve Actuators: How to Select a Valve Actuator

Difference Between a Vented Ball Valve and a Standard Ball Valve

Our Posts

View AllWhat is a Spool Valve and How Does It Work?

Spool valves are incredibly useful. They are a simple directional control valve used in hydraulic an …

Read MoreWhat is the cracking pressure of a check valve?

Check valves, regardless of their individual design, serve the specific purpose of permitting the fl …

Read MoreSmart Water Valves: Futuristic Flow Control Technology

Leaks can range from annoying to devastating, and the longer they go unaddressed, the more costly th …

Read MoreHow to Calculate Flow Rate In Water Systems

Flow rate is critical in water systems, from simple home plumbing to complex industrial water system …

Read MoreWhat Is a Valve Pressure Rating? Definition and Guide

Pressure ratings are important considerations when designing a system that uses valves, but they can …

Read MoreSpecial Pricing and Services for OEM - the ValveMan Valve Store

OEMs or Original Equipment Manufacturers make up a large portion of our clients at ValveMan. With th …

Read MoreData Cooling Centers and Sanitary Valves

Overheated data centers pose a massive challenge, and the global data center cooling market is growi …

Read MoreValve Materials for Gaseous Oxygen Service

Oxygen may seem safe because it is colorless, tasteless, and odorless, but in the wrong conditions, …

Read MorePneumatic Actuators Valve Types

Have you ever stopped to think about what makes an automated assembly line push, pull, lift, and rot …

Read More-320°F Liquid Nitrogen Cryogenic Control Valve Setup

Need a valve that can handle -320°F liquid nitrogen without freezing up — and still control flow? He …

Read MoreWhy Fall is the Perfect Time for Valve Maintenance (And What Happens If You Wait)

We're well into fall now, which means it's time for that conversation nobody wants to have: winter p …

Read MoreFrom the DMZ to Bonomi: Rick Wentzel’s Valve Legacy

In the inaugural episode of the Fully Open podcast, host Gil Welsford sits down with Rick Wentzel of …

Read More

Check Valve vs Backflow Preventer Comparison | ValveMan

If you need to make sure that fluid in your pipe system flows in one direction only, and prevent rev …

Read MoreDifferent Types of Gas Shut Off Valves | ValveMan

Whether you're upgrading your residential gas system, looking for the best gas shut off valve for yo …

Read MoreGlobe Valve vs Ball Valve Comparison Guide | ValveMan

Valves are widely used in industrial and manufacturing facilities, but they’re also used in utilitie …

Read MoreNEMA Ratings Explained | ValveMan

Have you ever wondered what that little NEMA number on your electric actuator meant? Or perhaps, you …

Read MoreGate Valve vs Ball Valve Comparison Guide | ValveMan

Valves are widely used in industrial and manufacturing facilities, but they’re also used in utilitie …

Read MoreValve Inspection - Main Points of Valve Inspection and Testing in Manufacturing Settings

Industrial facilities rely on different types of valves (such as gate valves, check valves and ball …

Read MoreCan Ball Valves Be Used For Flow Control?

Ball valves are widely used in plumbing and piping systems, in fact, they are one of the most common …

Read MoreIntroducing Bonomi Valves

The Bonomi Group is a leader in industrial sectors including oil and gas, hydraulics, heating and en …

Read More

888-825-8800

888-825-8800